Waste management in the European Union is an important part of the transition to a circular economy and shaping waste policy is based on the “Waste Hierarchy”, which sets the order of prioritization at operational level: Prevention (preparation), reuse, recycling, recovery and the least favored option disposal.

However, in some cases it is not possible to prevent waste generation and due to the nature of industrial processes, waste generation occurs. In these cases, most of the waste has to be transferred to third parties (Environmental Permit and License Regulation) for further treatment.

Further treatment processes generally vary depending on the type of waste (Waste Management Regulation Annex-4 Waste List two digit code: 01-20) and subsequent use purposes, and some waste treatment systems and facilities continue their activities to serve multiple purposes for this reason.

This approach is not new and has been preferred since the 1960s. Today, there are more than 10,000 facilities serving this purpose in Europe and at least 50 commercially available hazardous waste treatment technologies (166/2006/EC; 2010/75/EU). The main purposes of the waste processing technologies used in these facilities are briefly as followings:

- Reduction of hazardous characteristics of wastes,

- Separation of some or all of the waste into separate components that can be subjected to subsequent use / treatment,

- Reducing the amount of waste that needs to be sent to final disposal,

- Transforming waste into a useful material.

In addition, in order to fulfill the purpose of waste treatment the facilities also include a number of important auxiliary activities related to waste treatment, such as the acceptance and storage of waste waiting to be treated on-site or diverted off-site. The waste sector is highly regulated for this reason.

The recycling of waste oils is also an integral part of the waste treatment industry and has been strictly regulated in the EU for more than 40 years. Directive 75/439/EC, which came into force for this purpose, obliges waste oils to be collected and disposed of without harming people and the environment, the important amendments were made in 1987 to prioritize the refining of waste oils for energy recovery instead of incineration.

In addition, the Waste Frame Directive (WFD) requires member states to take strict measures to ensure the separate collection of waste oils, preventing their mixture with other wastes and, if possible, with other types of oils. This is aimed at managing waste in a manner that respects the waste hierarchy and avoids harm to human health or the environment.

On the other hand, as stated in the European Green Deal, the European Union is striving for a climate-neutral and circular economy within the context of a non-toxic environment to prevent pollution.

Further developed in the Circular Economy Action Plan and Zero Pollution Action Plan, it is expected to contribute to meeting these targets through strong environmental management of waste oils, with emissions and discharges minimized and waste oils largely converted into base oils.

At this point, it is of great importance to use state-of-the-art techniques, in other words best available technologies (BAT), under economically and technically favorable conditions in order to prevent and control potential industrial pollution and to ensure a high level of human health and environmental protection. For this purpose;

BAT 42 requirement: Waste input (chlorinated solvents, oils with PCBs) in refining plants should be continuously monitored as part of waste pre-acceptance and acceptance procedures in order to improve the overall environmental performance.

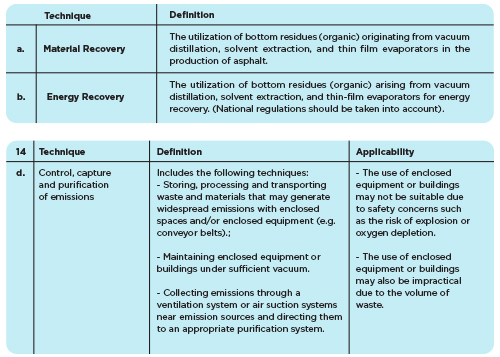

BAT 43 requirement: In order to reduce the amount of waste sent for disposal, one or both of the following techniques should be used:

BAT 44 requirement: In addition to BAT 14d, one or more of the following techniques should be employed to reduce emissions of organic compounds that may be released into the air.

- Adsorption

- Thermal oxidation

- Packed tower