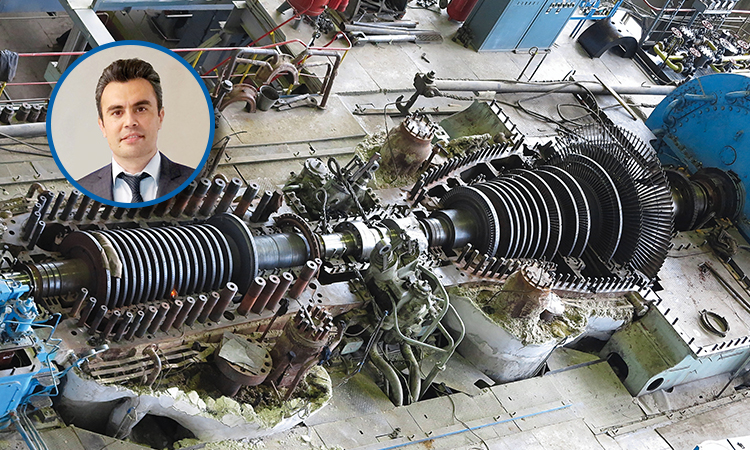

Diversification efforts in energy production put forward steam and gas turbines. However, the problem of varnishing in such turbine systems is an important problem that causes a decrease in performance and increase in maintenance costs. In this article, we will focus on varnishing problems in steam and gas turbines and discuss the solution strategies and current technological innovations.

Origins of varnishing

Varnishing in steam and gas turbines can often be caused by ambient conditions, operating conditions and fuel quality. Oil, dust, water vapor and chemical components accumulate on turbine components and cause varnishing. Especially, the decline in the condition of the lubricant over time and the deterioration of the additive package due to aging can cause serious problems. This can reduce the efficiency of turbines and cause long term performance losses.

Solution strategies

- Smart coatings and surface technologies: Special coatings and surface technologies can be used to prevent varnishing problems. Nanotechnology based coatings can reduce deposition on turbine surfaces and facilitate cleaning.

- Optimization and maintenance strategies: The operating parameters of steam and gas turbine systems must be regularly optimized. This can reduce the risk of varnishing and improve turbine performance. Furthermore, planned maintenance strategies can minimize the effects of varnishing.

- Air quality control: Air quality around the turbine should be monitored regularly and filtration systems should be used to minimize negative impacts. Especially, the control of pollutant gases and particles can prevent varnishing.

- Heating and cooling system: On-site heating and cooling systems can be used to prevent varnishing of turbine components.

- Lubricant analysis: In order to determine the varnishing in the oil, it is important to test according to ASTM D7843 method. In this way, the amount of soluble or insoluble varnish is calculated and the varnishing potential is determined. Then, determining the usability of the oil, the amount of remaining additives and its resistance to oxidation will provide information about the action to be taken.

Technological advances

- Sensor and monitoring technologies: Smart sensors can detect varnishing of turbine components at an early stage. This enables more effective maintenance strategies to be implemented.

- Artificial intelligence and data analytics: Artificial intelligence and data analytics can analyze varnishing trends over large data sets and provide guidance to optimize turbine performance.

Varnishing problems in steam and gas turbines can be overcome with technological developments and appropriate solution strategies. Innovations such as smart coatings, monitoring technologies and artificial intelligence have the potential to minimize the effect of this problem. With advances in the energy sector it is possible for steam and gas turbine systems to become more efficient and durable.