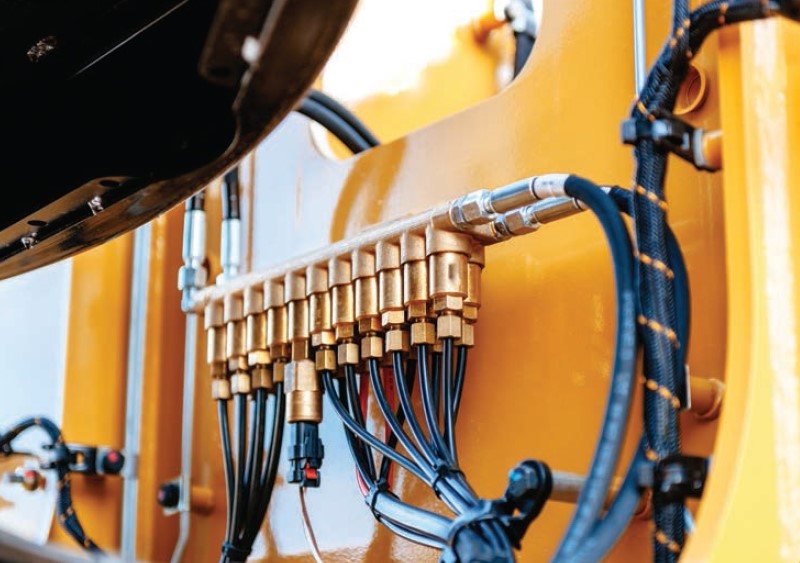

The science of hydraulics is based on the use of a pressurized fluid to transmit force (Pascal's Principle). This fluid can be gas, water, oil or any other fluid. With the help of this fluid, it helps to perform tasks such as molding, rotation, forming, lifting, etc. Therefore, it is widely used for commercial and industrial operations in various areas such as construction machinery, control valves in factories, pumps, lifts, medical surgery devices, and many others.

Why hydraulic systems?

- The system can work uninterruptedly under full load.

- Parameters such as force, torque, speed can be easily controlled.

- Several machines can be controlled with a single hydraulic system.

- It can be controlled at areas that requires quick or precise action.

Since it has such a widespread use, the supply of hydraulic oils naturally increases. So, which path should we follow when choosing a hydraulic oil? Although oils used for commercial purposes are only considered as oil for the end user, they are divided into two: mineral and synthetic oils. While the difference between mineral oil and synthetic oil is commonly considered only in terms of price, there are huge differences in the background. However, when evaluating this, it will be useful to follow the steps below so that we can compare price and performance first.

The first step is to answer the question ‘in which application the oil will be used'. Is my equipment an industrial stationary equipment or a mobile equipment (e.g., a crane)? Although manufacturers define their oils for both conditions, additive packages may differ for application areas. In this case, I will have to consider my additional needs.

In the second step, if I will use the oil in the food sector, I must consider whether it is Food Grade and the toxic properties of the oil. If my equipment is to be operated in a high risk area with 'High temperature, flash’ properties, I need to consider whether the oil I will buy is resistant to heat.

The third step is to answer the question 'in which environmental conditions will I run this oil'. If my equipment will operate in very dirty and harsh environmental conditions, it will be beneficial to have a detergent and dispersant additive package in my oil. If the same oil will circulate in a combined system and be used in equipment operating at different temperatures, it will be beneficial to use an oil with a high viscosity index. If there is a high load and wear risk, it will be beneficial to have an extreme pressure additive and/or an anti-wear additive in the oil.

After choosing our oil with these parameters, I want to call attention to a blind spot that I have determined based on my industry experience: the purchase decision is made without checking the compatibility of the oils used in the system with each other and/or with the sealing elements. When adding oil to the system, if these oils are not compatible with each other in terms of groups (Group I, II, III, IV or V), the oil cannot deliver the desired performance, early oil degradation may occur and this may lead to serious equipment damage. If the selected oil is not compatible with the sealing elements, it can cause wear on the elements such as the gaskets in the system, and problems such as breaking, disintegration and as a result oil leaks may be encountered. For this reason, it is of great importance that the explanations on the technical information sheet of the oil overlap with the oil requirements specified by the manufacturer.