“Reduced CO2 emissions equal increased profitability.” This is the simple but important message emanating from a new energy consumption study of industrial-scale grease production, revealing a new relationship between environmental and economic targets.

Our results show for the first time how grease producers can achieve a sustainable, energy-efficient, and profitable manufacturing process by making smart choices with regard to the base oil and technology they use,” says Nynas Naphthenics’ grease specialist and Senior Technical Advisor Mehdi Fathi-Najafi.

Faced with the challenge of reducing the carbon footprint of highly energy-intensive processes, there is little wonder that manufacturers of lubricating grease are looking for guidance. Hence, a ground-breaking investigation into the energy consumed in the making of lithium-based greases, which represent around 75 percent of the global grease production, is attracting industry-wide attention.

“This study could be a milestone in assessing grease production in terms of significantly reduced CO2 emissions, and in doing so, it will help to increase the awareness within our industry of the impact we have on the global environment,” says Mehdi Fathi-Najafi.

Conducted by Nynas in collaboration with the reactor manufacturer Stratco and the grease manufacturer Eldon’s SA, the study is the full-scale continuation of a joint Nynas/ Stratco pilot-scale investigation. That study revealed the potential for energy consumption reductions of around 12 percent per unit weight of produced grease.

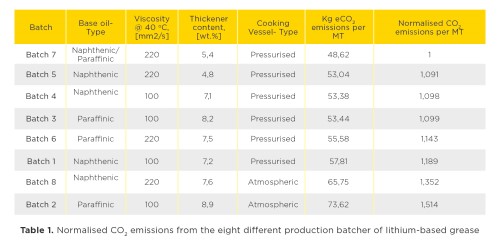

“For this industrial-scale study, we made eight batches of 8 tons of lithium-based grease. We used a pressurised (Contactor) reactor and a traditional open kettle vessel for the ‘cooking’ phase of the twostage process, which enabled us to compare the energy consumption impact of these two alternative technologies.”

To assess the impact of different base oils, the team used both paraffinic Group I oils and hydrotreated naphthenic oils as well as a blend of these two API grades. Furthermore, two average viscosity grades (100 and 220 cSt respectively) were used.

In line with the expectations from the pilot-scale study, the full-scale investigation concluded that the energy consumption and associated CO2 emissions can be significantly reduced in what is the most energy-intensive production activity within the lubricants industry.

Towards a more sustainable process

- “For a more sustainable grease process, switch from paraffinic base oil in open kettle to a paraffinic/naphthenic blend in a pressurised reactor.” This is one piece of advice in the presentation voted “best paper” at the 2019 ELGI conference in Athens. “Grease Production, CO2 emission…a New Relationship!” shows how a smart choice of base oil and production technology offers environmental as well as economic advantages.

- Based on the production of eight industrial-scale batches of lithium-based grease, the research team found that CO2 emissions could be significantly reduced.

- Considering the test batches with the same base oil viscosity, the results emphasise that, for the grease with an oil of ISO VG 220, an overall reduction in CO2 emissions of 32.2 percent can be achieved by switching from paraffinic base oil in an open kettle to a paraffinic/naphthenic base oil blend in a pressurised process. These reductions in the emissions due to lower energy consumption and lower thickener content entail lower production costs. The naphthenic oil used in Batch 5 and Batch 7 (Table 1) was NYNAS T 600.