Writer: Chemist – R&D Expert Sedanur Birincioğlu

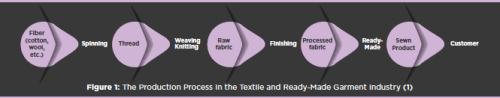

The lubricant industry collaborates with the textile industry to lubricate textile machinery, enhance its performance, and prolong its lifespan. In addition to machine oils, mineral, synthetic, and plant based oils are used in various stages of textile production.

In Türkiye, the textile industry is one of the leading industries with its share in GDP and employment, investment infrastructure, and high export rates. The textile industry in Türkiye, which has a voice in the global market and competes with countries such as China, India, South Korea, Pakistan, and Vietnam, is heavily reliant on imports in terms of machinery and chemical substances used in production.

The textile industry is interacting with agriculture and livestock industries for natural fiber needs; the petrochemical industry for synthetic fibers; the chemical industry for dye and finishing chemicals; and numerous secondary industries in terms of accessory use. In addition to machine oils, mineral, synthetic and plant based oils such as blending, cone, spin finish, knitting, weaving, and bobbin winder oils are used in textile production.

The knitting process is the fastest system that converts thread into the fabric structure. In terms of loop formation types, fabrics are divided into two categories.

- Machines with weft knitting systems

- Machines with warp knitting systems

A suitable lubricant is used in accordance with the method chosen.

The Importance of Knitting Oils

Textile lubricating oils are made by combining additives with mineral oil and are used to ensure the efficient operation of textile machinery. Textile lubricating oils protect the production quality of modern textile machinery while also allowing for faster operations.

These lubricants may potentially increase the operating time of the equipment, reducing maintenance requirements. It also reduces noise and vibration during operation, as well as the risk of unscheduled downtime.

It is well known that textile oil producers provide chemically resistant products which can be used at various temperatures. It is preferable that the oils do not leave stains on the produced fabrics in case of a leakage. Therefore, these oils must be easily washable without affecting the product quality.

Textile machinery oils provide a more comfortable user experience in terms of vibration and noise while reducing the maintenance requirement and damage risk.

Principle of a Circular Knitting Machine

There are various fabric knitting methods for textile machines. Circular knitting machines, one of these methods, are examined in terms of working principles, requirements, current status, and prospects.

Circular knitting machines are those that allow fabric knitting by moving 1750 to 3000 needles around a bushing in a circular plane. By winding the knitted fabric around the fabric winding cylinder, the fabric is cut to the desired sizes and the knitting procedure is carried out.

The following are some of the benefits of knitted textiles: being cheap, requiring high-quality threads, the ability to easily change design patterns, comfort, and well insulation. Demand for knitted textiles is expected to rise in the coming years.

Components Used in Knitting Oils

- High-quality base oil (22,32,46 cSt)

- Anti-wear (AW)

- Friction reducer

- EP additive (EP)

- Corrosion inhibitor

- Antioxidant

- Emulsifier

Which Standards Does the Knitting Oil Meet?

- DIN 62136

- OEKO-TEX Standard 100

- Compatibility with GOTS & REACH Standards

- ZDHC (Zero Discharge of Hazardous Chemicals)

- ISO 9001

- ISO 14001

- Optional Groz-Beckert

- Optional Mayer&Cia

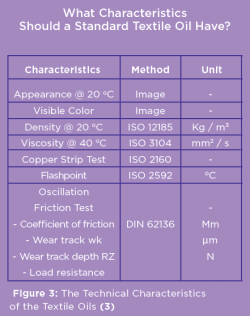

DIN 62136 or the ASTM equivalent for this standard is sought in knitting oils primarily for physical appearance and meeting the desired performance. Organic fabric producers also demand GOTS or OEKO-TEX certifications. The certification of oil by global circular knitting machines’ and these machines’ platinum needle producers is important in terms of prestige and suitability.

Global Textile Oil Companies

Nye Lubricants, Inc.,

Total S.A.,

Klüber Lubrication,

The Chemours Company,

BENJN R. VICKERS & SONS LTD.,

BRÜCKNER Trockentechnik GmbH & Co. KG,

Eni S.p.A.,

Matrix Specialty Lubricants B.V.,

CARL BECHEM GMBH,

Eldons Lubricants Industry.

Considerations When Using Knitting Oils

- The lubricant in the correct color and viscosity for the machine and application should be used.

- The lubrication adjustment must not be much or less.

- The increase in thread dust and the temperature in the machines’ location cause difficulty in operations. Therefore, temperature, fabric and thread dust must be kept away from the machine.

- The oil storage conditions must be monitored. Precipitation of the additives in the oil may occur in extreme cold. In this case, use oil only after it has completely thawed and become homogeneous.

The Global Market Size and Predictions for the Knitted Fabric

In the USA, the knitting textile market was worth USD 4,568.9 million in 2019. It is expected to rise to USD 6,090.1 million in 2027. The following countries are among the countries with the largest share in this market size: Germany, India, France, China, and Canada. The knitted fabric market’s growth trend is expected to benefit the lubricant industry, with which it is in contact.

The knitted fabric market’s growth trend is expected to increase the demand for textile oils.

The Future of Knitting Oils

Lubricants, which interact with many industries directly or indirectly, play a significant role in the textile industry. Lubricants made from mineral, plant-based or synthetic oils, sometimes improve the performance of fibers and threads, and sometimes improve the performance and lifecycle of textile machinery. It is also critical to discuss the importance of the end user’s application method, storage method, and proper product selection, in addition to the chemicals (additives) used and the quality of the base oil.

Globally, sustainability, circular economy, and minimum use amounts, which are frequently on the agenda of Europe in particular and for which sanctions have been imposed, are also being discussed in Türkiye. In terms of organic fabrics, the textile industry, in particular, tends to produce fabrics that are not exposed to noxious chemical substances and use less water. Beyond being producers or users, as individuals, we need to develop a high awareness and consciousness of environmental impact, especially in the petrochemical sector.

“We’re at war with nature. If we win, we’re lost.”

Hubert Reeves