The amount of used waste lubricant is dependent on the consumption of lubricating oil. The more oil is used, the larger the amount of recoverable waste oil that can be generated. Used oils are collected at designated locations, such as service stations with significant potential, industrial and commercial establishments and specific facilities established for this purpose. They are stored in compliance with regulations.

Waste oil acquires hazardous characteristics as a result of possible organic pollutants present in the base oil, degradation of additives over time added to base oil to provide various properties, wear and tear on metal equipment that the oil comes into contact with, corrosion, and other factors. Treating waste oils mixed in water in domestic wastewater treatment plants that operate using biological treatment techniques can be challenging. For such types of waste, both chemical treatment and biological treatment techniques should be used. Special methods are required to clean waste oils that are mixed with soil. Due to the presence of toxic substances, waste oils are considered a pollutant that poses a threat to human health.

The high levels of polycyclic aromatic hydrocarbons (PAHs) found in waste oil can cause damage to the skin of individuals regularly exposed to the waste oil. This can lead to irreversible and persistent skin diseases, and even cancer. In oil changing operations, waste oil storage areas, transportation and in the recycling and disposal facilities, the person who comes into direct contact with waste oil should use protective clothing, gloves, glasses, and if there is a possibility of splashing, a mask as well. If there is a continuous exposure to waste engine oil, it is advisable to use appropriate gloves or aprons made of neoprene, nitrile or n-butyl rubber. In case of skin contact with waste oil, it is important to wash skin thoroughly with plenty of water and soap, and a protective cream should be applied to prevent skin from cracking.

Oil changes should be conducted at the lowest possible temperature, and during these procedures, exposure to waste oil vapor or smoke should be avoided. Due to the low volatility of waste engine oil, the risk of generating hazardous vapors at normal ambient temperatures is low. Exposure to vapors or fumes generated through thermal decomposition can be hazardous. Individuals who experience irritation in the nose and respiratory tract or start coughing as a result of inhaling waste oil vapor should be immediately moved to an area with clean air. If these effects continue indefinitely, it is important to seek medical assistance.

Waste oils can be temporarily stored by waste oil producers within their operational area or at locations where lubricant sales and/or changing take place. Additionally, waste oils are also stored within premises of waste oil recovery (refining) and disposal facilities for certain periods of time until the waste oils are processed. If the relevant regulations regarding the storage of waste oils are followed, ensuring compliance with the specified technical conditions, there should be no harm to the environment and the human health.

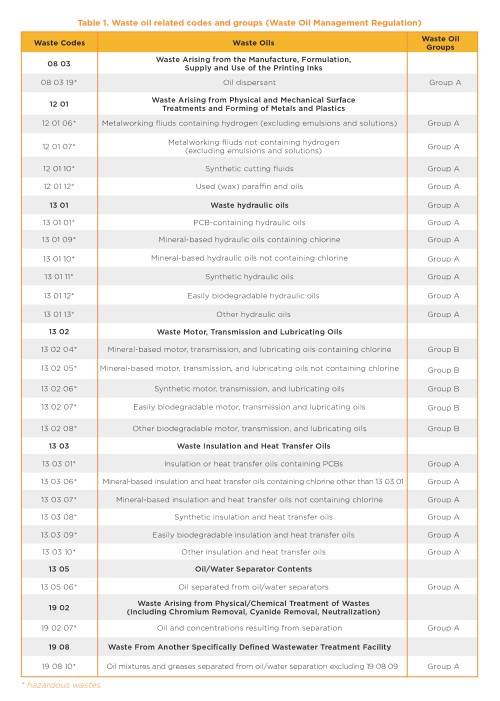

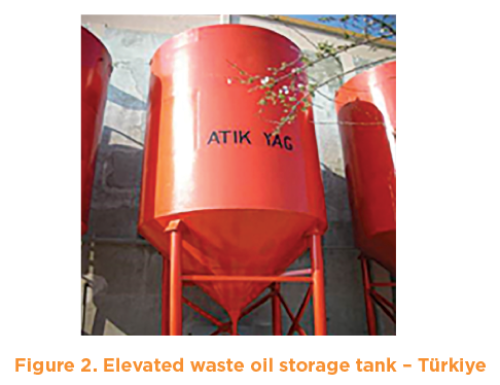

Places where oil changes are performed, such as vehicle service centers and fuel stations, should collect different types of waste oils from various categories separately (Table 1). They should be stored in red-colored, rainwater-protected containers or tanks placed on an impermeable surface. The containers should have a minimum capacity of 200 liters and a maximum capacity of 1250 liters, and must be labeled with the inscription “Waste Oil”. It is important to avoid mixing the waste oils with water, solvents, toxic substances, hazardous materials, or other wastes.

According to the Waste Oil Management Regulation, waste oils are categorized into two groups as A and B. Only waste oils within the same group can be collected (stored) together and allowed for mixed accumulation.

The following rules should be followed when delivering waste oil.

- Informative posters for consumers should be displayed at locations where oil changes are performed,

- When storage tanks are full, engine oil manufacturer or authorized organization should be called and notified,

- Tanks at the waste oil transfer point should be red-colored and labeled with the inscription “Waste Oil” as well as surrounded by a containment area with a capacity at least equal to the tank’s volume,

- There should be an adequate supply of absorbent material available for collecting spilled oil,

- Necessary precautions should be taken to prevent fire hazards,

- The interior of the overflow containment area should be sealed with epoxy paint or insulating material,

- Waste oil notifications should be made through the waste management and tracking system MoTAT,

- The vehicle’s license document should be checked, and if the waste to be delivered is engine oil, a document verifying whether the delivering vehicle belongs to an Authorized Organization or engine oil manufacturer should be requested, and the license document should be verified,

- Waste oil producers should fill out the waste declaration form using the online applications prepared by the Ministry, starting from January of each year and no later than the end of March, including the information from the previous year. They should confirm the form, take a printout, keep a copy of the disposal record for 5 years, and have it readily available for inspection when requested.

The recommended basic storage features for waste oil storage are applicable to almost all hazardous chemicals. The storage area should be labeled according to the chemical properties or hazard class of the stored substance. Corridors, doorways, and entrance/exit points should be kept clear. Adequate lighting and ventilation should be provided in the storage area, and the temperature should be maintained at the stable level.

Fire extinguishers should be accessible and in working condition. Open flames, heat sources, or direct sunlight should be prevented from entering the storage area. Chemicals should not be stored in restrooms or fume hoods. Only toxic gases should be stored in gas cabins or fume hoods. Chemicals should not be stored on the floor, balcony, or window sills. Only approved storage cabins should be used for storage purposes. Shelves should be stable and securely fastened to walls or any immovable points. Measures should be taken to prevent shelves from getting contaminated by chemicals. Shelves should be mounted in a location away from sunlight, open flames or heat sources. Large bottles or containers should be stored at a height of up to 60 cm from the floor. Corrosive chemicals should be placed on lower shelves.

In various sectors, the quantity of waste oil generated varies depending on the nature of the activity. Consequently, the size of the containers used for waste oil storage may also change. However, regardless of the quantity of waste oil generated, it is necessary to ensure impermeability of the floor in areas of the facility that come into contact with waste oil. For this purpose, the reinforced concrete floor and containment walls, with a minimum thickness of 25 cm, should be coated with isolation materials such as epoxy paint, geomembrane, or similar materials to ensure impermeability and protection against spills. Waste oils should be stored in tanks or containers placed on impermeable flooring.

There is no specific standard for tanks used for the storage of waste oils in Türkiye. However, due to the fact that waste oils are of petroleum origin, it is necessary to comply with the TSE 3298 and TSE 4943 standards published by Turkish Standards Institution. Safety principles for waste oil storage tanks should be determined in accordance with the standard TSE 4943, titled “Safety Rules in Tank Farms for Crude Oil and Petroleum Products Storage”. The characteristics of these tanks should comply with the standard TSE 3298, titled “Welded Tanks Used for Crude Oil Storage”. It is recommended to use elevated tanks for safety and ease of access. Waste oil tanks should be placed within a containment area with a capacity at least equal to the tank’s volume to prevent overflow.

The area where the tanks are located should have foam fire suppression systems and aqueous tank cooling systems. Waste oil temporary storage tanks and containers should be equipped with level indicators. They should have measures to prevent overfilling and be filled only up to the designed level. Waste oil temporary storage tanks/containers should never be left completely full and should be easily fillable and dischargeable.

The tanks/containers should have sufficiently sized and closed intakes. They should be equipped with the necessary arrangements for the removal of accumulated solid or sludge-like sediments at the bottom when required, and protected from rainwater. The tanks/containers should be red-colored and labeled with the inscription “Waste Oil”, and no foreign substances such as water, gasoline, fuel oil, paint, detergent, solvent, antifreeze, or diesel should be mixed into these tanks.

The measures to be taken in case of waste oil spills many vary depending on the characteristics of the area. In the event of a spill, it is important to promptly intervene and isolate the spill area from clean areas using appropriate materials. In soil and concrete areas, the spread of waste oil should be controlled by using sawdust, perlite, sand, soil, or special absorbent materials. In soil areas, contaminated soil that has come into contact with waste oil should be cleaned as soon as possible, considering the vertical and horizontal spreading distance and the proximity to groundwater and surface water sources. In various concrete surfaces, in the event of a spill, nearby sewer connection channels should be closed, and the waste oil should not be cleaned towards wastewater drainage systems.

In case of waste oil spills into the sea, appropriate equipment can be used to facilitate the removal of oil-contaminated water. Additionally, under the guidance and recommendations of authorized institutions, the use of cleaning/diluting agents is possible. When waste oil spills occur in enclosed spaces, proper ventilation should be ensured and the use of masks is recommended.

Waste oils may contain a certain amount of fuel or flammable liquids depending on their usage and storage areas. Therefore, in waste oil fires, there is a risk of toxic vapors being released due to the fuel or flammable liquids involved. Foam, dry chemical powder fire extinguishers, or water mist should be used in waste oil fires. For small-scale fires, carbon dioxide fire extinguishers, sand, and soil can be used. However, pressurized water should not be used. The use of halon gas fire extinguishers, which can cause environmental pollution, is not recommended.

Against the risk of waste oil boiling and spilling out of the tank/container where the fire occurs, direct spraying onto the tank/container should be avoided. Water can be used to cool down the surrounding areas and objects exposed to the fire. In order to intervene in waste oil fires in enclosed spaces, the individuals involved should be trained personnel equipped with adequate protective gear. In cases of fires involving waste oil, entering the fire area without personal protective equipment and respiratory devices should be avoided due to the harmful effects of combustion products or risks arising from oxygen deficiency.