Waste oil recovery is the process of removing all kinds of pollutants, oxidation products and particles in the waste oil and obtaining base oil or petroleum products in accordance with national or international standards, specifications and intended use. The success of recovery depends on obtaining high efficiency and quality products, avoiding damage to air, water and soil as a result of recovery processes and minimizing waste generation.

According to the Turkish legislation, real and legal persons wishing to engage in waste oil recovery activities must obtain a license from the Ministry of Environment, Urbanization and Climate Change. According to the license procedure, it is obligatory to obtain “Conformity to Turkish Standards” from the Turkish Standards Institute in order to certify the conformity with the standards of the products obtained as a result of recovery and “Lubricant Manufacturing and Trading License” from the Energy Market Regulatory Authority in order to sell these products to the market.

Basic Steps in Modern Recovery Processes

- Distillation

Distillation is the process of separating the components of a liquid mixture by partial evaporation followed by condensation, taking advantage of the difference in evaporation properties. Classifications such as continuous – batch according to the mode of operation; dual system – multiple system according to the feed current; single stream – multiple streams according to the number of product streams received; azeotropic-extractive-salt-added according to whether additional feed current is used in the separation process; tray column-packed column according to the column internal structure are possible. In processes such as refining and recovery of base oils from crude oils, the most common distillation types are vacuum distillation in packed columns and water removal in flash evaporators.

- Vacuum distillation

In base oils, compounds have high boiling points. For boiling such compounds, it is preferable to reduce the pressure instead of raising the temperature. Vacuum distillation method is used for these substances both to prevent energy loss and due to environmental factors. In addition, high distillation temperature requires high preheating temperature, which accelerates the formation of malfunctions such as coking in the furnace.

- Atmospheric distillation

Since the boiling points of base oils are not suitable for atmospheric distillation, vacuum distillation is preferred. However, in order to separate the lighter components in a feed stream, the flash distillation technique, which is a one-step process, is suitable as a first step. In flash distillation, the feed stream is separated into liquid and vapor streams in equilibrium with each other. The composition of the streams depends on the amount of feed evaporated.

- Separation from asphalt with propane

Crude oil contains asphalt as well as many other components. Asphalt constituents are undesirable substances because they cause high viscosity, discoloration and high carbon balance in lubricants. Asphalt is concentrated in the residue at the bottom of the vacuum distillation tower. The propane de-asphalting process is a liquid/liquid extraction process where propane is used as a solvent. The process is based on the principle of propane not dissolving high viscosity materials and dissolving low viscosity materials. Since asphalt is the highest viscosity element of crude oil, it does not dissolve in propane during extraction and forms precipitate and separates from the environment. The efficiency of the process is directly related to temperature and propane dosage.

- Thin film evaporator

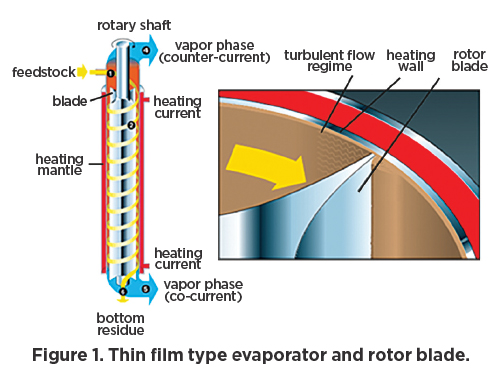

Thin film evaporators are an attractive and accepted solution for the basic processes such as distillation, gas purification, concentration, drying where difficult and complex problems are encountered. It is classified differently as horizontal and vertical according to its position, cylindrical and conical according to its design, co-current and counter-current according to its working principle, and also according to the type of rotating shaft and blade it contains. In general, it consists of a cylindrical surface surrounded by a heating mantle and a shaft which distributes the product on the heated surface in the form of a thin

film layer with the help of rotating blades. The shaft type can be designed with a fixed clearance between it and the wall or with adjustable clearance if the shaft is conical. The majority of thin film evaporators are designed as vertical type with a fixed clearance shaft. The product enters the equipment tangentially to the heating zone and is distributed homogeneously on the inner surface of the cylinder body by means of a rotating shaft. It is then transferred over the wall following a spiral path with a swirling flow regime and optimum heat flow with the movement created by the rotating shaft. The volatile components are rapidly vaporized and leave the equipment for condensation, flowing either in the same direction or in the opposite direction to the feed stream. The vapor stream is condensed outside to obtain the product. The non-volatile components are removed from the bottom residue.

- Hydrogenation

The processing of lubricants, especially motor oils, is carried out with classic acid/clay technologies, but the oil recovery efficiency cannot reach the desired levels with these technologies. To overcome this problem, catalytic hydrogenation of dewatered and purified from residual fractions waste oil is the preferred method. Hydrogenation is a more commercially viable alternative to waste incineration and chemical treatment processes. Catalytic hydrogenation has long been recognized as a modern and successful refining process in terms of efficiency and quality of the finished product. The process is based on the principle of contact of the oil fraction with a solid catalyst in a pressurized hydrogen environment. The flexibility of the process, resulting from the selection of the appropriate catalyst and operating conditions, makes it possible to apply it to a wide range of products, from the lightest to the heaviest. The operating conditions may vary depending on the reactions required and the nature of the oil fractions to be hydrogenated.

Figure 1. Thin film type evaporator and rotor blade.

- Solvent extraction

Solvent extraction is based on the separation of one or more of the components in mixtures, usually in liquid solution, with the help of a solvent. The first step in this three-step separation process is the contacting of the solvent and the mixture. In the second step, the separation of the two separate phases (solvent-rich phase, extract and solvent-poor phase, raffinate) is carried out and finally these phases are subjected to distillation for solvent recovery and solution separation. Solvent extraction is a simple process; used oil and solvent are mixed in appropriate proportions to ensure complete mixing of the base oil in the solvent. The solvent is then recovered by distillation for recycling purposes. The solvent extraction process is capable of removing approximately 10 – 14% of the used oil as contaminants, roughly corresponding to the amount of additives and impurities normally present in used oil.

- Furfural extraction

In the liquid-liquid extraction process, aromatic compounds and other impurities in distillates and de-asphalted oils are extracted with furfural, a selective solvent. Furfural has high solvency for compounds that are unstable to oxygen and other undesirable substances such as dark coloring agents, resins, carbon-forming structures and sulphur compounds. The feedstock oil is fed into the extraction column at a temperature predetermined point, the raffinate phase is drawn from the top of the column and the extract phase is drawn from the bottom. The extract phase is cooled and the separated raffinate is sent back to the extraction column. The raffinate and extract are subjected to multistage solvent recovery processes. The raffinate contains high quality base oil. The by-product extract is used as a raw material.

- NMP (N-Methyl-2-Pyrrolidone) extraction

Since NMP is a highly selective solvent, the desired quality product can be obtained with high efficiency at low solvent to oil ratio. The raw material and NMP are fed into the extraction column at the temperature and flow rate that will provide the optimum conditions required for countercurrent extraction. The raffinate mixture exits the top of the column, passes through the heat exchangers and into the raffinate flash column.

Here most of the NMP is evaporated, separated from the raffinate and returned to the extraction column. The raffinate, which is the stream exiting the flash column, is fed and NMP is withdrawn by vapor. The NMP-rich extract mixture exits the bottom of the column, passes through heat exchangers and the NMP is separated in an efficient evaporation system. The NMP-free extract is withdrawn by steam and sent to the extract stripper.

- Adsorption process with clay

Waste oils with different boiling temperatures contain impurities (such as chlorophyll, which gives undesirable color) even when treated with sulfuric acid after fractionation. These impurities can be retained by utilizing the adsorbent properties of clay. Although this process aims to remove impurities and contaminants remaining after dewatering and refining, lighten the dark color and eliminate odor, clay bleaching does not lead to the production of high quality base oils as in solvent extraction or hydrogenation, but it is easier and cheaper to implement in terms of process. Since the solid waste products generated after this process are classified as hazardous waste, they go for final disposal (incineration) or used as additional fuel in cement plants.

- Recovery process for energy purposes: Incineration

Due to the high thermal value of waste mineral oil, it is possible to provide energy recovery by using the energy of waste mineral oils that cannot be recovered, by incineration in facilities that have received a hazardous waste disposal license from the Ministry of Environment, Urbanization and Climate Change. Incineration plants must have a final combustion section connected to the combustion chamber, and the first chamber temperature in the incinerator must be at least 900°C. The temperature must be continuously recorded and kept under control. There must be an additional burner in the final combustion section, the burner must be activated automatically when the temperature falls below the lower limit, the minimum combustion temperature in this section must be 850°C, 11s00°C for substances containing more than 1% halogenated organic and the retention time must be at least two seconds. Facilities are obliged to comply with emission limit values throughout their operational activities.