High performance gear oils are expensive, but mandatory for demanding applications such as industrial gearboxes. Evonik has developed the NUFLUX® technology to optimize fluid service costs, reduce downtime and increase productivity.

Tough operating conditions and high-performance demands, such as smaller sumps, constrained cooling capacities, increased loads, harsher temperatures, and faster speeds, are influencing the design of industrial gearboxes now and in the future. High performance gear oils are more expensive but provide longer service intervals and longer equipment life than traditional gear oils while still meeting technical performance requirements. Industrial gear oils made with NUFLUX® technology, created by the Oil Additives Specialists at Evonik, provide excellent performance and cost-effective formulations.

NUFLUX® helps to save time and money

Using their VISCOBASE® synthetic base fluids, Evonik has created a methodical approach to help oil marketers formulate gear oils that meet or surpass OEM specifications and international standards. Securing robust hardware, long service life, and high load-carrying capacity at a very appealing cost position presents oil marketers with numerous chances to meet the technical and business needs of their clients. For industrial gear lubricants, Evonik‘s NUFLUX® technology has been designed to have optimal fluid service costs, reduce downtime, and increase productivity.

NUFLUX® formulated gear oils come with five certified ISO viscosity grades, from ISO VG 150 to 680. Industry standards like DIN 51517-3, AGMA 9005- F16, ISO 12925-1 CKD, GB 5903 CKD, GB/T 33540.3 and numerous strict OEM requirements can be met by NUFLUX® formulations that use NEXBASETM, YUBASETM or low viscosity PAO as base oils. Other API Gr. III base oils are also possible to be used in NUFLUX® formulations and grant OEM approvals. At present, NUFLUX® formulations demonstrate reductions in operating temperatures and enhancements in scuffing and micropitting. With VISCOBASE® and API Group III base oils, two NUFLUX® ingredients, even high ISO grades like 300 and 1000 can be formulated.

Testing NUFLUX® formulations against DIN 51517-3 for CLP Oils yields good results. NUFLUX® formulations tested better than required, in some cases much better, in many aspects such as viscosity index, pour point, foam behavior, demulsifying, aging behavior, load carrying capacity, and roller and cage wear.

A variety of applications with better results

Reduced sump sizes may result in increased strain on the oils and gearboxes. As load, temperature, and speed expectations rise, it‘s getting harder to keep up with maintenance. NUFLUX® delivers a solution for various applications such as cement, mining, steel, fracking systems and wind power. All of these are characterized with harsh industrial conditions, particularly high load, high stress, and high temperatures.

NUFLUX® offers a significantly longer service life of gearboxes due to less wear, less micropitting, and better bearing protection, less or no damage to equipment durability, and achieves better energy efficiency, and overall lower cost of operation.

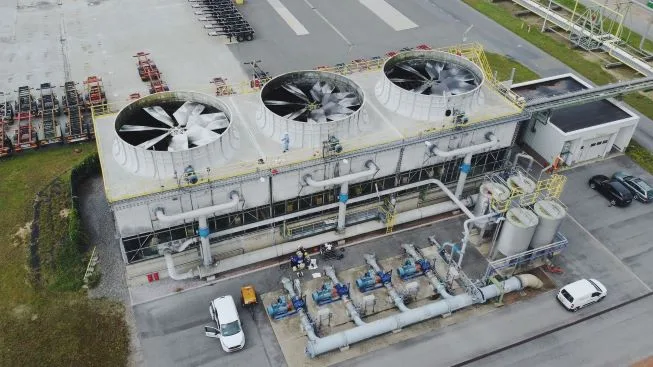

A case study with Cooling Towers

Harsh operating environment and high-performance expectations are shaping the future of industrial gearbox design. Besides this, the industry is also becoming more sustainable. Reduce energy demand in operation, reduce overall CO2 emissions, maximize reliability of equipment and reduce maintenance efforts are just some of the challenging requirements faced by the key industry players nowadays. For industrial equipment to operate efficiently and meet the sustainability vision, it needs high performance lubricants for gears.

Evonik produces lubricant components for oil manufacturers that improve the properties of the finished formulated lubricants and is currently also deploying oils containing its synthetic base stocks at Evonik manufacturing sites. The aim is to create real life case studies, extending the number of references and to demonstrate the performance of the technologies, reduce costs and emissions and support customers with the results.

The use of NUFLUX® technology is proving to be successful not only in terms of operating performance but also offering sustainable solutions – NUFLUX® formulated gear oils, compared to PAO based formulations, offer a reduction in carbon footprint of approximately 50%. Oil manufacturers offer such formulations as part of their industrial gear oil portfolio and Evonik manufacturing sites make use of these commercially available lubricants.

Three Cooling towers located in the Evonik site of Antwerp, Belgium, have three ventilators driven by Hansen gearboxes, each filled with 65 liters of ISO VG 220 mineral oil. Overheating of the gearboxes, especially in summertime, was one issue that the operation team had to deal with.

Figure 1. Changing the oils of gearboxes are challenging and time-consuming activities.

The mineral oils have been replaced by NUFLUX® based oils ISO VG 220 in 2023. After 6 months of the oil changes, the operating temperature of the gearboxes reduced by approximately five degrees Celsius.

| OilSep-23 | Mineral 22061 oC | Mineral 22063 oC | Mineral 22060 oC |

| OilApril-24 | NUFLUX® 22054 oC | NUFLUX® 22057 oC | Mineral 22058 oC |

| Difference | -7 oC | -6 oC | -2 oC |

Figure 2. Measured temperatures at gearboxes before and after 6 months of oil change, upgrading from mineral oil ISO VG 220 to NUFLUX® based gear oil ISO VG 220.

As a result, the system works more efficiently and reliably. In addition, the oil change interval is extended – a major advantage, as gearboxes are often difficult to access, making oil changes time-consuming and costly.

These results prove that changing to efficient lubricants is a fast track to reduce Total Cost of Ownership and emissions. They are also very valuable for the marketing of our lubricant components, and, at the same time, we are ensuring greater efficiency and energy savings at our sites by using these oils.

Check the video available at Evonik Youtube Channel to see more details of NUFLUX® technology deployment at our Antwerp site!

| Deep-Rooted Collaboration Between ADCO and EVONIK Evonik, the world’s leading specialty chemicals manufacturer, has been operating in Turkey for over 40 years under the distributorship of ADCO. Specializing in versatile additives and high-performance methacrylate ester-based products, the German company Evonik has expanded its deep-rooted, trust-based partnership with ADCO to include Georgia, Kazakhstan, Uzbekistan, Turkmenistan, Kyrgyzstan, and Tajikistan, in addition to Azerbaijan and Bulgaria. ADCO General Manager Selçuk Akat expressed his satisfaction with the interest Evonik has received in the Turkish market for its high-quality and superior-performance products. He emphasized that the NUFLUX technology will provide time and cost benefits for Turkish companies. Akat stated that they will represent Evonik in much wider geography with the experience they have gained in the Turkish market and that they will always continue to support their customers in terms of product supply and technical assistance. ADCO, the leading distributor in the lubricants and fuels sector in the Turkish market since 1977, represents the German company Evonik by undertaking their lubricant additives distributorship. |