Electric vehicles (EV) are vehicles that get their kinetic energy from one or more electric motors. Unlike internal combustion engine vehicles, they use entirely electric power instead of gasoline or diesel. They are driven by electric motors and powered by batteries. The electric motor creates a rotating magnetic field thanks to the electromagnets inside, and the rotational movement is transmitted to the powertrain and turns the wheels.

The main difference between electric vehicles and internal combustion engines is that electric vehicles do not use conventional engine oil. However, there are still fluids needed.

- Cooling fluid: Special liquid cooling systems that are used to cool the battery, motor and power electronic components.

- Transmission fluid: Specially formulated low viscosity fluids that are needed for transmission and driveline elements.

- Brake fluid: As in conventional vehicles, brake fluid is needed to operate the brake system.

- Windshield washer fluid: Windshield washing is mandatory in all vehicles.

- Other grease and oils: Specially formulated greases to be applied on bearings, gears, etc. in electric vehicle drive mechanisms.

In short, although the need for major engine oil maintenance in internal combustion engines has disappeared, electric vehicles still require a variety of fluids, especially thermal management fluids.

EVONIK, one of the specialty chemical companies that produces additives for lubricant production, is ready for new technology. VISCOPLEX® and VISCOBASE® product groups include additives and formulation recommendations that provide the desired properties for electric vehicles.

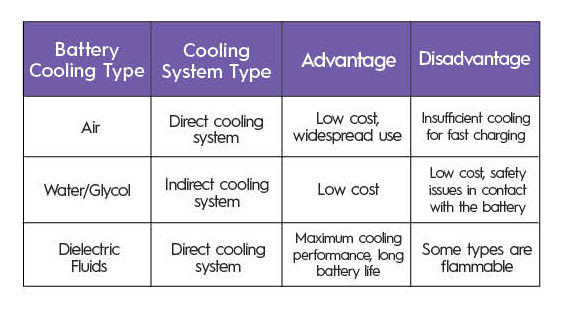

Battery Cooling System Types and Features

Some systems are used to ensure heat management of battery packs in electric vehicles and prevent overheating. Battery performance is temperature sensitive and the ideal operating temperature is preferred to be between 15-35°C. Battery cooling systems play a critical role in extending battery life and ensuring safe operation.

Depending on the vehicle model, battery capacity and cooling system design, an average of 5-15 liters of cooling fluid is needed.

Specially formulated cooling fluids are needed for battery and engine cooling systems in electric vehicles. The main properties of these fluids are:

- Low electrical conductivity: High conductivity in fluids that directly contact battery cells can cause battery damage or even explosion. Therefore, coolants with low or zero conductivity are preferred.

- Anti-corrosion properties: It is important to prevent corrosion against metals such as aluminum, copper and steel in the battery pack. In this way, system life is extended.

- Wide temperature range durability: The cooling fluid must support the battery’s performance at various temperatures. Good heat transfer properties must have a good heat conduction coefficient for efficient cooling of the battery.

- Preventing foaming and bubble formation: Foam and air bubbles are undesirable as they will reduce heat transfer.

- Proper viscosity: The fluid must have a suitable viscosity to ensure its pumpability and fluidity.

Typical components of battery coolants in electric vehicles

Typical components of battery coolants in electric vehicles often include water and glycol-based mixtures. However, there is the development of more effective ester-based coolants that are beginning to replace water/glycol mixtures. In addition, ion exchange resins, insulating plastic agents, corrosion inhibitors, antifoaming agents and coloring dyes are also added to these mixtures.

NYCO Synthetic esters are vital to improve the performance of vehicles, increase efficiency and reduce emissions in the era of e-mobility. They offer superior properties, especially in matters such as safety, heat transfer performance, lubrication quality and material compatibility.

The standards developed or being developed by ASTM (American Society for Testing and Materials) for electric vehicle coolants are of great importance.

ASTM D8485 – Specifies a test method for evaluating the effect of electric vehicle coolants on metal corrosion.

WK80854 – A new specification standard for waterfree, dielectric coolants is being developed.

WK76375 and WK83561 – New standard test methods proposed to assist electric vehicle designers and coolant manufacturers.

WK52011 – A new specification standard proposal for glycol-based coolants. Fuel cell, battery and hybrid vehicles are used.

ASTM Committee D15 on Engine Coolants and Related Fluids is responsible for developing and maintaining standards for electric vehicle coolants.

2023 Global Electric Vehicle Sales Data

In 2023, full electric and plug-in hybrid vehicle sales increased by 31%, reaching approximately 13-14 million. [2] This figure corresponds to 16% of total global vehicle sales. [2] Tesla leads the global market in BEV sales with 1.8 million units in 2023. [4]. In some countries, such as Norway, more than half of new vehicles sold in 2023 are electric vehicles.

2023 Global Electric Vehicle Coolants Market Size and Future Forecasts

While the value of the electric vehicle (EV) coolants market in 2023 is estimated to be 297.2 million dollars, the value of the EV battery cooling system market is approximately 2.93 billion dollars. [5][6] The coolants market will reach 3.7 billion dollars by 2033. The EV battery cooling system market is expected to reach 12.28 billion dollars with an annual growth rate of 15.39% in the 2023-2033 period.

These data show that although the EV coolants market is relatively small, it has great growth potential in the coming years with the rapid expansion of the electric vehicle market. Manufacturers continue to invest in advanced cooling systems and fluids to extend product life and increase safety by maintaining ideal temperatures of vehicle components. Growth will accelerate due to regulatory compliance and efficiency demands.

References

1.https://insideevs.com/news/707891/global-ev-sales-Hit Record 1.5+ Million In December 2023

2..https://ourworldindata.org/electric-car-sales

3.https://cleantechnica.com/2024/02/06/tesla-still-1-inworld-bev-sales-2023-world-ev-sales-report/

4.https://www.futuremarketinsights.com/reports/evcoolants-market

5.EV Battery Pack Cooling System Market: A Global and Regional Analysis, 2023-2033 ID: 5933026

6.McKinsey & Company EV Fluids Say Goodbye To The Oil Change

7.IEC 61099:2010 – Insulating liquids – Specifications for unused synthetic organic esters for electrical purposes

8. https://corporate.evonik.com/en

9.https://www.nyco-group.com/markets/synthetic-esters/