Petrol Ofisi continues potently its R&D investments to develop the product portfolio with the vision of meeting future energy needs by closely following the sector dynamics in order to be “ready for tomorrow”.

One of the recent projects undertaken by Petrol Ofisi, aiming to meet the rapidly evolving and growing electric vehicle market needs, was presented at the annual general meeting of the European Lubricating Grease Institute (ELGI) held between April 29 and May 2, 2023. The presentation was given by Sevda Şahan, the Director of Petrol Ofisi Technology Center (POTEM), and Ece Korkut, Petrol Ofisi R&D Engineer.

General information

The performance requirements of greases depend on their application areas and the needs of these application areas. Greases are used to reduce energy losses caused by friction in the lubrication of bearings without a lubrication reservoir where liquid oils cannot adhere.

The lubricants used in Internal Combustion Engines (ICEs) are engine oils, chassis and wheel bearing greases, transmission/differential fluids, as well as break and coolant fluids.

Hybrid Electric Vehicles (HEVs) use engine oils similar to ICEs but require advanced technical specifications. They also utilize chassis and wheel bearing greases, transmission/differential fluids, as well as break and coolant fluids.

Electric Vehicles (EVs) do not use engine oil, but they still require the use of chassis and wheel bearing greases, transmission/differential fluids, as well as brake and coolant fluids.

The lubrication techniques applied to EVs and HEVs, which have higher torques, operating temperatures and operate in an electromagnetic field compared to ICEs, are not as efficient as those used for ICEs. EVs have more electrical components than ICEs.

Commercial conventional lubricants and greases have the potential for use in EV applications but their tribological, electrochemical and thermal properties need to be improved to meet the requirements of EVs. Therefore, it is expected that lubricants for EVs will have less interaction potential with electricity compared to conventional lubricants and greases. These are some of the different features that lubricants for EVs and HEVs need to have:

- Thermal conductivity and heat transfer

- Compatibility with elastomers and polymers

- Better corrosion protection (including copper corrosion)

- Improved friction protection

- Enhanced wear protection

- Higher operating temperatures

Additionally, new testing methods are being developed for the analysis of these characteristic needs. Brief information about the characteristics is provided below.

Electrical conductivity

EVs have more electrical components compared to ICEs. Therefore, it is expected that EV lubricants will have less potential for interaction with electricity compared to conventional lubricants and greases.

The electric field can degrade greases through chemical changes. The high electrical conductivity of oils encountering an EV’s engine can lead to short circuits. Therefore, lubricants used for this purpose should have low electrical conductivity.

To avoid electrical discharge or electrical damage, the effect of electrical resistance is more critical than the effect of the dielectric constant. For this main purpose, the greases used should have low electrical resistance and high dielectric constant. The dielectric strength of the lubricant can be optimized through a change in the base oil. Similarly, the use of additives can assist in optimizing the dielectric strength of the oil.

Thermal conductivity

EV applications generate higher heat compared to ICEs under operating conditions. Therefore, lubricants used in EVs need to have good thermal stability. It is expected that E-greases and E-lubricants will be improved in terms of heat transfer and cooling capabilities compared to conventional lubricants. The thermal conductivity property is affected by structure of the base oils used.

Elastomer/polymer compatibility

The body components of EVs include new compounds, new types of polymers and different elastomers compared to ICE’s. Lubricants will encounter these new and diverse materials. Therefore, lubricants used in EVs should have better material compatibility.

Corrosion prevention

The components of EVs and HEVs are generally made of copper. Lubricants used in EVs should have low copper reactivity because they are exposed to a larger copper surface.

Wear resistance

One of the expected performance characteristics of E-greases is good wear protection. The addition of AW (anti-wear) and EP (extreme pressure) additives tends to compromise the sliding stability performance of greases.

Stability

The addition of EP ad AW additives generally affects the lifespan of greases. When adding EP and AW to E-greases, careful consideration is essential, and making the right choices during this process is critical. Moreover, E-greases should have good resistance to thermal and electrical degradation.

Operating Temperatures

E-greases should have higher operating temperature performance capabilities. They are typically applied in wheel bearings. EVs, especially in electric motor bearings, require greases with higher dropping points. However, higher operating temperatures tend to reduce the lifespan of greases.

Resistance to water

Water and various types of additives reduce the breakdown voltage of oils. EVs and HEVs should have high water resistance to eliminate the possibility of electro-wetting.

The use of nanoparticles (NPs) in e-greases

One of the most successful approaches in developing EV lubricants from ICE oils is the use of nano-based friction modifiers. Adding NPs to oils can improve their heat capacity, enhance tribological performance and increase thermal conductivity due to the increase in the energy carriers in the system. Carbon nanotubes (CNT) have a wide range of application and exhibit excellent thermal and electrical conductivity. They can maintain their stability up to 750°C in open air.

Titanium and Molybdenum are transition metals and have solid lubricant forms known as TiO2 and MoS2, respectively. Several studies have reported that TiO NPs enhance tribological properties. Research is being conducted to show that TiO2 and MoS2 NPs show better tribological performance in lubricants compared to other NPs.

Grease soap types and base oil choice

One of the most popular types of grease soaps in the market is lithium based-greases. Lithium/lithium complex and polyurea greases are the ones commonly used to lubricate the wheel bearings of vehicles.

The base oil used in EV lubricants should have a high viscosity index, high heat capacity, thermal conductivity and cooling properties. To enhance energy efficiency in lubricating EVs and HEVs, the use of low-viscosity oils in greases is recommended.

Experimental design

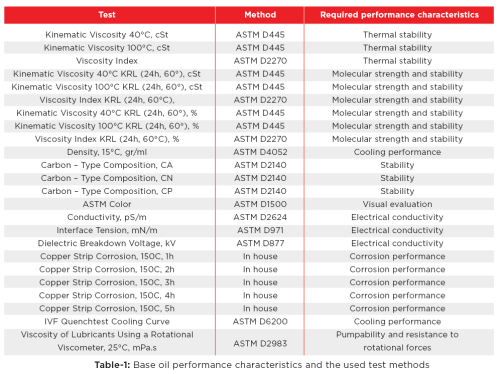

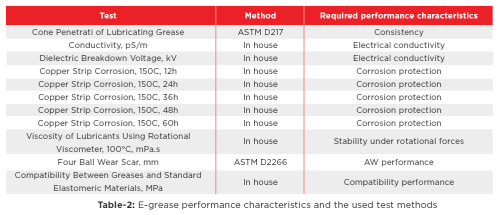

The development process of EV/HEV greases should start with the selection of base oil. The choice of base oils in this study has been made based on the parameters listed in Table-1.

In the selection of base oils, particular focus is given to copper corrosion performance, electrochemical properties, thermal characteristics, as well as elastomers and polymer compatibility. Moreover, new standard test methods are being developed for the analysis of these new characteristic needs.

Standard test methods as well as revised test methods to characterize new and different performance characteristics were applied to evaluate the performance properties of the developed product. Based on our information, there is no established standard test method to measure the electrical conductivity, dielectric breakdown voltage, viscosity changes and compatibility of greases. Developing E-greases is challenging for several reasons. The grease samples used in this study were formulated and produced at the Petrol Ofisi Technology Center (POTEM) Laboratory. The formulation steps for E-greases should generally be determined according to the requirements of the operating conditions.

Throughout the study, references used were thoroughly shared in the ELGI presentation.