The health of each individual is directly proportional to the values of our blood. If there is no infection in our blood, it is an indicator of our health. This principle applies to the condition of the oil within our equipment as well.

According to the research, 70% of machine failures are attributed to oil contamination. The contamination of the oil prevents the formation of an effective oil film, leading to secondary wear and significantly reducing the lifespan of the respective equipment components such as bearings, gears, hydraulics, and others.

Contamination, is the term used to describe the process of becoming dirty or polluted. Contaminant refers to all foreign materials that are not designed for or naturally present in a system. Examples of contaminants include dust and water, while oil additives can be shown as examples of wear particles. For example detergent additives commonly used in motor oils are not present in hydraulic or turbine oils. These additive substances are contaminants for hydraulic oils and can also be considered as contaminants for hydraulic equipment. These contaminants lead to the degradation of the oil, depletion of existing additives in the oil, inability of the oil to perform its functions, and potential machine failure due to tribological damage.

Water is a common contaminant that can be found in machinery lubrication systems. It can enter the system from sources such as condensation, coolants or environmental conditions surrounding the equipment. This condition leads to the oxidation of the oil, resulting in corrosion on the surfaces of the equipment.

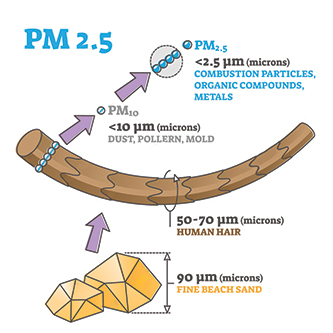

Particle contamination also has a critical impact, especially on equipment such as servo valves, turbines, hydraulics, etc. Particle contamination is so small that it cannot be seen with the naked eye. The particle size is smaller than 40 microns.

A healthy human eye can detect particles of approximately 70 microns in size. Assuming that a salt grain is 100 microns and a human hair is 70 microns, it is not possible to see particles smaller than this level with the naked eye. That is why you cannot detect the contamination in an oil sample just by looking at it with the naked eye.

The particle contamination of relevant critical equipment can be determined using the ISO 4406 test method. Additionally, the detected high contamination can be removed through an appropriate filtration method in accordance with the manufacturer’s guidelines. After the removal of particle contamination in the oil, the causes should be investigated. The question of whether it is externally sourced (such as dust, sand, etc.) or internal to the equipment (such as iron, copper, etc. due to wear) needs to be answered. After the identifying the root cause, appropriate correct actions should be taken to address the issue permanently.

Improving the storage conditions of the oil is important for maintaining the clean and sustainable oil health. Additionally, equipping open areas above the equipment with suitable filters, regularly replacing filters, and inspecting sealing elements can significantly prevent failures caused by contamination.