It is as important to know the chemical structure and application areas of the greases we use in our critical equipment and to closely monitor the analyses in this respect as it is to monitor the liquid lubricant analysis.

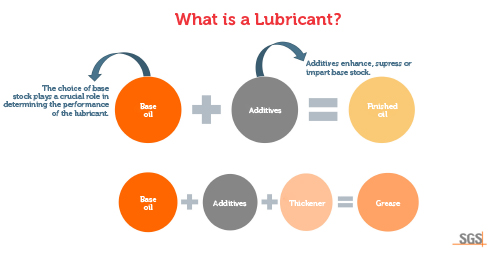

In lubricants, the final product is obtained by adding base oil and additives, while in greases, thickeners are additionally added. These thickeners are usually derived from metallic soaps such as aluminium and lithium and are used to give the grease a solid or semi-solid form. The final product to be used in the equipment has a near-perfect load carrying capacity and the ability to operate at high temperatures.

The application areas of oils and greases are different. The reasons for favouring greases over liquid lubricants are described in SAE Information Report J310, Automotive Lubricating Greases, published by the Society of Automotive Engineers, as follows: “Greases are often used in place of fluids where a lubricant is required to maintain the condition of the equipment within the mechanism, particularly where opportunities for frequent relubrication are limited. This requirement may be based on the physical configuration of the mechanism, the type of movement, the type of seal, or the need for the lubricant to fulfil all or part of any sealing function in preventing loss of lubricant or ingress of contaminants. Greases do not fulfil the cooling and cleaning functions associated with the use of liquid lubricants, mainly due to their solid nature. With these exceptions, greases are expected to fulfil all other functions of liquid lubricants.”

In other words, besides cooling and cleaning, greases have common purposes with liquid lubricants such as reducing friction, resistance to oxidation and sealing properties. Whether these properties protect the equipment they are used in can be checked by performance tests carried out in a laboratory.

In order to monitor these analyses in a proper trend, as always, the initial work starts with taking a representative sample. In order to take a representative sample, a 50 g sample that can be drawn from the main load center is sufficient. The sample is taken with a syringe if the equipment is a bearing and the center of the bearing can be reached. In cases where the center of the bearing cannot be reached, the sample can be taken by transferring to a clean sample container by scraping with a clean stainless-steel spatula.

It is of great importance that the sample reaching the laboratory is in sufficient quantity and the sample information is complete. So what is the sample information required by the laboratory?

- Brand/type of grease

- Time of use of grease

- Grease volume

- Date of sample collection

- Equipment brand model and operating hours

- Sample collection point

If the sample to be analyzed is unused grease, it must be subjected to performance tests. The basic tests in this regard are as follows:

Dropping Point Test: The dropping point of grease is the temperature at which the thickener can no longer hold the base oil. Grease is placed in a small container and heated in an oven-like device. When a drop of grease falls from the bottom opening of the container, the dropping point of the grease is calculated using the temperatures inside the oven and the container.

4 Ball Weld Test: A 12.7 mm steel ball is rotated against three fixed balls of the same size. Grease surrounds the balls. Test conditions are 1770 rpm, 25°C and 10 seconds duration. The test steps continue with new balls and increasing load until four balls are welded.

In the case of used grease, it is recommended to carry out elemental analysis, water content and wear particle index tests.

In the light of all this information, the contamination and wear levels and performance test results determined after the analysis will help to determine the potential failures of the relevant equipment within the scope of predictive maintenance, to determine whether the relevant grease is suitable for the environmental conditions to be used, whether it is suitable for the machine and to help maintenance engineers to plan maintenance for possible failure. At the same time, it will give an idea whether the grease used needs to be changed and how much refreshing should be done in the equipment.