Dear readers,

I will approach my column on the recovery of waste lubricants in two stages. In the first stage to be published in this issue, I will mention the importance of recovery and its methods in general terms, and in the second stage, I will give information on “fundamental steps in modern recovery process; adsorption process with clay and incineration recovery process for energy purposes.”

Waste oil recovery is the process of removing any contaminants, oxidation products, and particles in the waste oil and obtaining base oil or petroleum products for intended use in accordance with national or international standards and specifications. The success of recovery depends on achieving high efficiency and obtaining quality products, avoiding damage to air, water and soil as a result of recovery processes, and minimizing waste formation.

According to the legal regulations in Türkiye, individuals and legal entities wishing to engage in waste oil recovery activities are required to obtain a license from the Ministry of Environment, Urbanization and Climate Change of the Republic of Türkiye. According to the licensing procedure, it is mandatory to obtain “Turkish Standards Compliance” from the Turkish Standards Institution in order to certify that the products obtained through recovery comply with the standards, and a “Lubricant License” from the Energy Market Regulatory Authority in order to sell these products to the market.

The selection of the most suitable types of waste oil for recovery, collection and transportation of waste oil, selected recovery method, marketing of the products and evaluation or disposal of the waste generated as a result of recovery should form an integrated business management that complements each other. The recovery of waste oils is done in two ways:

- Lightly contaminated waste oils can be reused after undergoing simple processes of cleaning or improvement.

- Waste oils are subjected to the recovery (regeneration/refining) process to obtain base oil.

Regeneration is the process of removing all kinds of contaminants, oxidation products and particles from waste oils to obtain the original oil suitable for the intended use in accordance with national or international standards and specifications. The refining process involves refining of waste oils to transform into base oil or petroleum products in accordance with national or international standards and specifications. As a principle, it is an economical option to refine waste oils containing low amounts of water, fuel, sand, and similar contaminants and oxidation products, non-biodegradable and less than 50 ppm PCB/PCT to obtain base oil. Therefore, it is crucial that waste oils to be collected for recovery are separated at the source.

Waste Oil Recovery and Disposal Methods

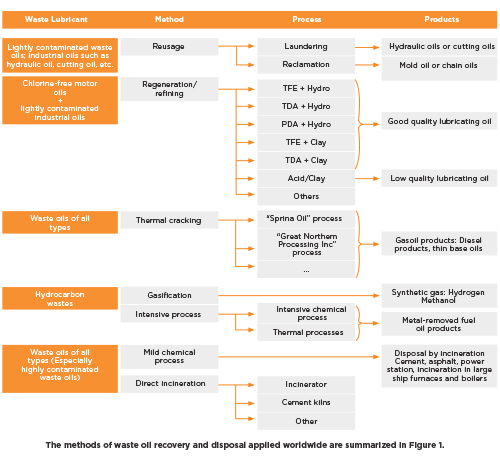

Today, various methods have been developed and put into practice for the recovery of waste oils. The choice of method varies depending on the contamination level, type and the desired product to be produced from waste oil. High quality recovered base oils obtained through the application of modern recovery methods such as hydrotreatment and solvent extraction are comparable to the original base oils. The quality of the base oil obtained through recovery varies according to the applied process and facility. The methods of waste oil recovery and disposal applied worldwide are summarized in Figure 1.

The economics of waste oil recovery largely depends on process costs, efficiency, disposal costs of waste generated as a result of recovery, energy and other consumption, emission control, the selling price of the recovered base oil and the cost of the waste oil. If these three factors are examined in detail, the factors that determine process costs are given below.

- Plant capacity: The cost of waste oil processing for a small capacity facility can be 20-40% higher compared to a large capacity facility,

- Location of the plant: Proximity of necessary infrastructures (wastewater-solid waste disposal facility, etc.) to the recovery facility,

- Technology used: The installation cost of modern technologies is approximately 75% higher compared to older methods such as acid/clay. For instance, hydro-treatment incurs a high start-up cost,

- The country of plant location: Labor, transportation, and other operational costs vary significantly depending on the country where the facility is located.

The selling price of the recovered base oil can be influenced by factors such as the original base oil price, the quality of the recovered base oil, the quality difference between the recovered oil and the original products, and the market’s expectation of quality, which can reduce the selling price of recovered oil and can be defined as marketing costs. Facilities that operate continuously and have low operating costs may have financial capability to purchase waste oil as their raw material. On the other hand, for facilities with high operating costs, if the price of the recovered oil is higher than the original base oil price, it may be necessary to provide waste oil free of charge or financially support these facilities.

Despite the high costs incurred as a result of the inclusion of collection and transportation costs in operating expenses in the recovery process of waste oils, it is not possible to talk about the economic profitability of enterprises with low recovery efficiency and product quality. The amount of waste generated as a result of recovery is also one of the most important factors in evaluating whether recovery facilities are environmentally beneficial or harmful.

Waste oil recovery methods are categorized into two main groups as traditional recovery methods and modern recovery methods. Traditional recovery methods are typically applied in the form of acid-clay process and distillation-clay process. Examples of modern recovery methods include the KTI (Kinetics Technology International) process, SNAMPROGETTI process, VAXON process, SOTULUB process, REGELUBE process, PROP process and ENTRA process.

Recovery methods

- Laundering and reclamation methods

Waste oils that are not heavily contaminated can be reused after simple physical and chemical processes. Laundering method involves removing solid particles from the waste oil by filtering, removing water and adding additives to the laundered oil. This method is applied for waste hydraulic and cutting oils that are not heavily contaminated. The reclamation method involves centrifuging and/or filtering the waste oil and is used especially for the cleaning of uncontaminated waste hydraulic oils. Oils laundered or reclaimed by applying these methods can be used in the production of cutting oil, mold oil, gear oil. These products must comply with the relevant standards.

- Regeneration-refining methods

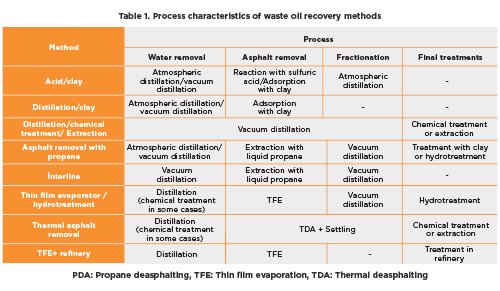

The process of waste oil regeneration/refining methods can be categorized into four groups: removal of water and light hydrocarbons (such as naphtha) from waste oil, removal of asphalt (asphaltic residues, heavy metals, polymers, additives and other degradation products), fractionation (2-4 fractions) and final treatments (removal of heavy metals, PAHs, other contaminants). Process characteristics of waste oil regeneration/refining methods are given in Table 1.