Türkiye’s first and only refinery to produce high-quality base oil from used lubricating oils with hydro-treatment technology; TAYRAŞ Base Oil Refinery

Establishing Türkiye’s first Group II base oil refinery with an annual used lubricating oil processing capacity of 60,000 tons, TAYRAŞ contributes to nature, the climate, and the national economy with the advanced refining technology it leads.

TAYRAŞ Base Oil Refinery in Bilecik, which is certified as a “strategic investment” by the Ministry of Industry and Technology of the Republic of Türkiye, successfully represents Türkiye’s refining industry in the world as a member of UEIL and GEIR.

During our visit to TAYRAŞ Base Oil Refinery we met with Ertuğrul Kılıç, Process and Operations Manager, and had a pleasant and inspiring conversation with him about the production capacity, technical competencies, and product quality of their facilities.

Could you tell us about the purpose of the establishment and the production capacity of your facility?

TAYRAŞ Base Oil Refinery was established to reduce the consumption of fossil resources by utilizing the most advanced refining technology available, as well as to convert used lubricating oils into base oils with high added value and a lower carbon footprint by environmentally friendly technologies.

In our refinery, used oils are processed and re-refining in to Group II base oils with high added value, and environmental pollution caused by waste oils is prevented. Thus, a product for which we rely heavily on global sources is supplied domestically and contributes to reducing the current account deficit. While our refinery supports the development of Türkiye in terms of technology transfer, training a qualified labor force, and providing employment, it also contributes significantly to indirect tax revenues (SCT and VAT).

Our refinery has been included in the scope of “Strategic Investment” by the Ministry of Science, Industry, and Technology of the Republic of Türkiye based on many evaluation criteria, such as TIDRABASE Base Oil production technology, the size of the investment, the employment provided, and the contribution to reducing import dependency with TIDRABASE Base Oils.

Could you please tell us about the technical infrastructure and technology of your facility?

Since the project and design phases, we have benefited from substantial international research and collaboration in the establishment of the TAYRAŞ Base Oil Refinery, with the goal of bringing the best available technology in this field to Türkiye. The supplier of this advanced technology, which has been successfully implemented at TAYRAŞ, is Sequoia Energy & Environment, an American technology design and engineering company. Our equipment is manufactured in the USA, India, Germany, the Netherlands, and Türkiye.

TAYRAŞ’ professional engineering team has extensive experience in this field through their leadership in the procurement, development, installation, commissioning, and operation processes. TAYRAŞ’ technical team has gained significant technological know-how through this technology transfer in order to build and commission a turnkey facility in the field of advanced technology base oil refineries.

TAYRAŞ represents Türkiye in the Union of the European Lubricants Industry Re-refining Section (UEIL) and the Groupement Européen de l’Industrie de la Régénération (GEIR), two of Europe’s well-established non-governmental organizations in the re-refining and lubricant industry.

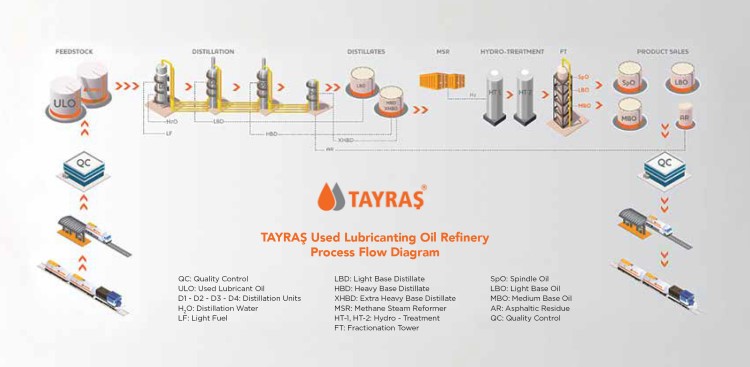

At our refinery in Bilecik, used oils are first subjected to a complex distillation process and then hydrotreated under high pressure in order to produce high-quality, high performance base oils.

Could you please tell our readers about the production process at the refinery?

Refinery processes primarily start with the reception of used oils at the facility. Used lubricating oils collected from lubricating oil change shops and waste lubricants collected from industry are transported to the facility with appropriate vehicles and equipment and taken to the temporary storage area. Waste oils are analyzed in our TS/EN ISO 17025 accredited laboratory according to the limits set by the Waste Oil Management Regulation and are accepted to the facility if they meet the technical specifications.

The four-stage evaporator distillation process begins after waste oils are stored. In this process, the removal of wastewater and light fractions contained in the waste oils and the separation of the contaminants generated by the degradation of the additives result in asphaltic residue as the bottom product and distillates as the middle product. At the refinery, the hydrotreating unit is used to process distillates that have been separated from light fractions and contaminants.

What is the importance of hydro-treatment?

Our refinery is the first and only facility in Türkiye to produce high-quality base oil from used lubricating oils using hydro-treatment technology. Currently, the leading technology in this field is hydrotreatment technology. The hydrogen required for the hydrotreatment process is also produced at the facility. The hydrotreating process involves sulfur removal and the conversion of unsaturated hydrocarbons into a saturated structure. Thus, high- quality base oil (TIDRABASE) is produced as a final product with low sulfur content, high saturated hydrocarbon content, and a high viscosity index.

TAYRAŞ Base Oil Refinery is important in terms of laboratory competence. Can you please tell us about the activities in the laboratory?

At our refinery, we have a laboratory accredited by TÜRKAK with TS/EN ISO 17025 accreditation. Waste lubricants, refinery intermediate products, and base oils, which are end products, are analyzed in our laboratory, which has the latest and most advanced world-class measuring devices. The analysis of base oil parameters specified in the TS 13369 standard and the rigorous quality control of waste lubricants received by the refinery in accordance with the legislation are also carried out in our laboratory.

Could you tell us about the product quality that results from all these technological background and technical processes?

The base oil produced at TAYRAŞ Base Oil Refinery is defined as Group II and II+ quality according to the API (American Petroleum Institute) base oil classification, which determines the international evaluation criteria, and this definition refers to the high-quality base oil. Our product is marketed under the brand name “TIDRABASE” and is recognized as an “Environment and Climate Friendly Product” due to its properties.

TIDRABASE Group II base oils, which started to be produced in our refinery in 2022, are the first Group II base oils produced in Türkiye. Unlike Group I base oils, Group II base oils play an important role in the production of engine oils that require high performance. Prior to the production of TIDRABASE, the Turkish lubricant industry used to meet all of its needs from abroad. With the introduction of TIDRABASE, an important import substitute began to be met by domestic production, benefiting the Turkish economy by reducing the current account deficit.

What makes TIDRABASE environmentally and climate friendly?

Our product has a sulfur content of 50 ppm. This value is much lower than that of base oils produced from crude oil. The product is differentiated from other base oils by its high viscosity value, low evaporation loss, high saturated content and low aromatic hydrocarbon level. These are important features which lubricant manufacturers prefer for base oils, which are the main raw materials for the production of high-performance lubricants. The better the properties of the base oil, the lower the proportion of additives used in lubricant production.

It is known that 1 liter of waste oil pollutes 1 million liters of water. Therefore, proper, and widespread collection and recycling of waste oils with environmentally friendly methods are of great importance for our environment. On the other hand, base oils produced from crude oil consume limited natural resources. In fact, while only 1-3 units of base oil can be produced from 100 units of crude oil, 70 units of base oil can be produced from 100 units of waste oil thanks to advanced refining techniques. This means a significant efficiency gain.

TIDRABASE Group II base oils produced by TAYRAŞ are the first Group II base oils produced in Türkiye.

Production processes at TAYRAŞ Base Oil Refinery are almost entirely managed from the Process Control Room with an automation system.

Re-refining Process is the removal of all kinds of contaminants, oxidation products, and particles from waste oils to obtain high-purity and base oils for its intended use in compliance with national or international standards and technical specifications

TAYRAŞ’s advanced re-refining technology makes a great contribution to the environment in terms of low sulfur content, waste-to-product conversion, the removal of contaminants in waste oils through hydrotreating, the reduction of dependency on crude oil and efficiency

Is there an international consensus on the environmental benefits and efficiency of advanced refining technology?

Of course. According to Carbon Footprint and Life Cycle Analysis conducted by GEIR, an independent and expert organization, it has been proven that the production of base oil from used oils by hydro-treatment process provides more than a 50% reduction in total CO2 emissions compared to base oils produced from crude oil. According to the same analysis, this process has been shown to provide a 6-8 times advantage over base oils produced from crude oil in terms of pollutants that cause climate change and other pollutants that cause greenhouse gas emissions. Leading this environmentally friendly technology in Türkiye, TAYRAŞ has become the most important solution partner that the lubricant industry will need for the Green Deal, Circular Economy, Climate Change, Sustainability and Carbon Footprint Reduction efforts.

We also know that your projects have been awarded. We would like to announce these awards to our readers.

With pleasure. TAYRAŞ’s contribution to the environment, the national economy, and our industry gained recognition in a short time and won two prestigious awards in succession. We achieved great success at the “8th Productivity Project Awards (Verimlilik Proje Ödülleri)” organized by the Republic of Türkiye Ministry of Industry and Technology. A total of 593 projects participated in the competition and we were among the 24 finalists and won 1st place in the “Small and Medium Size Enterprises” category. We received the “Sustainable Innovative Recycling Company of the Year” award at the third “Türkiye Innovation Achievement Awards Ceremony,” organized by Strong Bosses Magazine. We believe that these awards, which increase our motivation and excitement, are proof of our success in the field of sustainability.

It is crucial to raise social awareness and consciousness about the collection of used lubricating oils, their re-refining and contribution to the economy. Do you believe that we are at the desired level in this regard?

Lubricants are an important part of our industry and our daily lives and require careful waste management in harmony with the environment. It is very costly to clean up the pollution caused by waste oil that is poured into the soil and water. It is estimated that approximately 650 thousand tons of lubricating oils are consumed annually in Türkiye and approximately 300 – 350 thousand tons of waste lubricating oil are generated. Unfortunately, waste lubricants often enter the unregistered market; they are used as so called “oil number ten” and fake diesel fuel. This situation not only harms the national economy in terms of productivity and tax losses but also poses a serious threat to the environment and climate.

If we can achieve waste lubricating oil management in accordance with the regulations, subject it to advanced refining, and reuse it in the industry as base oil, we will contribute to Türkiye’s current account deficit by 300 million dollars annually. As the lubricants industry, we import about five hundred thousand tons of base oil annually. Furthermore, considering that indirect tax losses due to the unregistered use of waste oils as fuel or their inclusion in fuels are around 200 million dollars annually, we can estimate that the economic benefit provided by advanced refining is even higher. For this reason, we attach great importance to raising awareness and consciousness among our stakeholders and the public on the proper collection of waste lubricants and we contribute to this process with our waste lubricant collection and transportation vehicles across Türkiye.