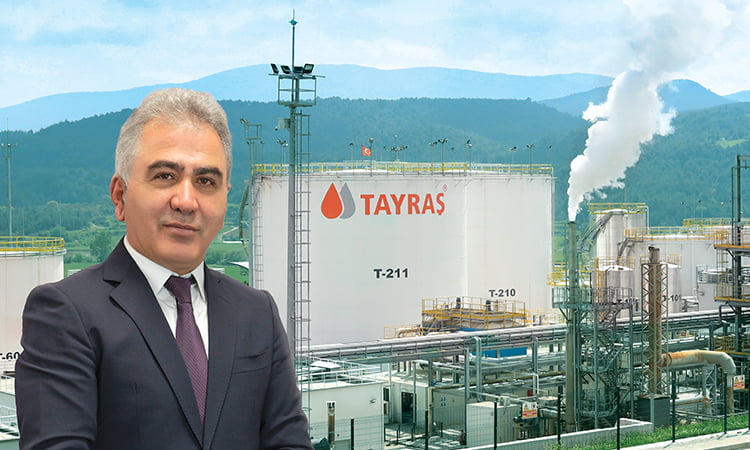

TAYRAŞ’ Chairman of the Board, Mehmet AFŞİN: We are creating added value through re-refining and taking pride in serving our country and the environment

In this issue, we are visiting the Chairman of the Board of TAYRAŞ Refinery, Mehmet AFŞİN, who introduced the concept of “re-refining” to Türkiye. Afşin emphasizes the importance of the used oil management and highlights the critical role played by TAYRAŞ in this process. He proudly talks about the quality and performance of TIDRABASE, a product derived from waste lubricants using hydro-treatment technology.

Mehmet AFŞİN, who is also the President of the Waste Oil Refining Industry Association (AYRASDER), explains the benefits of used oil management for the environment, sustainable development, and the national economy, while sharing the problems encountered in practice and proposing solutions.

Waste management, as one of the fundamental elements of the circular economy, is becoming increasingly important for the future of our planet, sustainable development, and the national economy. Just like in various other industries ranging from paper to glass, metal to plastic, awareness regarding waste management is raising in the waste lubricant sector as well. TAYRAŞ contributes to the technological developments in this field and adds value to the country’s economy by leading the sector with this important investment it has brought to our country and Group II+ base oils produced from used oils.

We talked to Mehmet AFŞİN, the Chairman of TAYRAŞ Base Oil Refinery leading the sector as a strategic stakeholder in waste management, about the ongoing projects and contributions of the company to the country’s economy.

As TAYRAŞ, you play a crucial role in the recovery and re-refining of used oils and turning them into value-added products. Could you please tell us about the benefits of these processes?

The re-refining of waste lubricants make a significant contribution to the environment and sustainable development, both in our country and globally. Waste lubricants, due to their toxic and polluting compounds, can cause persistent harm when they contaminate the soil and water. Similarly, when they are burned or used as fuel in an uncontrolled manner, they pose a threat to the environment and human health. From this perspective, we should view used lubricants not as waste but as an important raw material that contributes significantly to the national economy and environment.

As a result, the management of waste lubricants is regulated by a separate regulation from the Ministry of Environment, Urbanization and Climate Change, with a focus on the recovery of these oils through re-refining technology to obtain base oils. This approach transforms waste lubricants into an environmental policy. Therefore, the collection, transportation, refining and disposal of waste lubricants are subject to specific regulations and require licenses granted by the Ministry based on certain conditions.

On the other hand, the production of high-quality Group II+ base oils using advanced refining technology aims to meet the raw material needs of the lubricant industry. Consequently, the recovery of waste lubricants represent a significant added value in terms of our environment and national economy. As follows:

- Base oils produced from waste lubricants using advanced refining technology have a carbon footprint that is approximately 70% lower than base oils produced through crude oil refining. When compared in terms of toxic and polluting waste and the emissions they generate, base oils produced by refining used oils provide 5 to 8 times more advantageous results than those produced from crude oil. Therefore, base oils obtained from waste oils using appropriate technology and advanced refining process are highly environmentally and climate-friendly in terms of “low carbon footprint.”

- Base oils produced through the refining of waste oils also hold significant value for our national economy. This value not only brings benefits such as reducing current account deficit through the production of base oils from domestic sources (used oils) instead of relying solely on imports, but also adds significant value to the national economy through the reutilization of waste in the economy. This is achieved through the generation of additional VAT revenue and the collection of excise tax on the produced base oils. The full-capacity operation of TAYRAŞ for one year alone provides a direct and indirect contribution to the Turkish economy at the level of 50 million dollars annually.

When it is compared to practices in Europe where does waste lubricant management stand in Türkiye?

We can say that waste oil management legislation in Türkiye is more detailed and comprehensive compared to practices in Europe. European countries have established legal regulations prioritizing the refining of waste oils in accordance with the “Directive on Waste Oils” issued by the European Union. As a result, industrial-scale refining facilities have been established, operating within a structure that creates added value. We can identify two significant differences in waste oil collection and recovery processes in Türkiye when comparing to European countries:

- In Europe, waste oils are not subjected to informal and illegal practices as they are in Türkiye. Instead, they are directly delivered to refining facilities through technological solutions.

- In Europe, waste oil refining facilities are truly industrial-scale refineries, characterized by economies of scale and high-quality production. They are relatively few but distinguished as qualified and industrial facilities. In Türkiye, apart from TAYRAŞ, there are numerous small-scale facilities that operate using simple methods. At this point, TAYRAŞ is taking a leadership role in our country and the industry with our operational refinery, the production of Group II+ base oils, and examples of industrial refining.

TAYRAŞ’ refinery located in Bilecik stands among the leading refineries in Europe in terms of technical infrastructure, technology, and product quality. TAYRAŞ’ success is also recognized and accredited by the Union of European Lubricants Industry (UEIL) and the European Re-refining Industry Section (GEIR).

TAYRAŞ’ technical infrastructure and equipment have brought Türkiye to a competitive level with Europe in waste oil management. What would you like to tell us about TAYRAŞ’ technical capacity and competence?

TAYRAŞ Refinery is one of the most advanced refineries in terms of technology, both in Europe and worldwide. It is among the world’s best and most advanced refineries in terms of hydro-treatment technology and the quality of the produced base oil. The advanced technology refining and high-pressure hydro-treatment process we implement have positioned TAYRAŞ among the top facilities in Europe and the world in this field. Our production of Group II+ base oils, with low sulfur content, superior VI characteristics, and low carbon footprint has contributed to this ranking.

During the installation phase of our refinery, we conducted thorough technological research and prioritized making advanced technological investments. We also built a professional engineering team within our organization, enabling us to develop a strong expertise in the field. Therefore, we can confidently say that we have no deficiencies compared to Europe in terms of technology and process development. In fact, we have several advantages in many areas. This superiority has also been recognized by prominent European civil society organizations in the refining and lubricant sectors, such as Union of European Lubricants Industry (UEIL) and European Re-refining Industry Section (GEIR). We take rightful pride of bringing such an advanced facility to our country after years of dedicated efforts.

How does Türkiye perform in terms of waste oil collection?

It is possible to say that the recorded amount of waste oil collection in our country is significantly lower compared to European countries. If we provide a specific number, we estimate that approximately 300-350 thousand tons of waste oil is generated annually in Türkiye. According to the official records, the amount of waste oil that is registered, collected and officially documented as being recovered was around 70-80 thousand tons, based on the data from 2022. I believe that TAYRAŞ has made a significant contribution to reaching this level with our annual collection capacity of 60,000 tons. Nevertheless, when compared to EU countries, it is apparent that our recorded collection numbers remain at a considerably lower level. When considering together waste oil collection and its recovery as base oil in our country, I believe that the two areas where we may lag Europe are informal practices and public awareness. We have witnessed a significant development in the waste management sector in our country in recent years. However, I believe that there is a need for greater awareness both in terms of waste oil specifically and the entire waste industry. I have full confidence that the relevant government institutions and civil society organizations will take more steps towards raising awareness in the community.

The use of waste oil in fuel production or its involvement in illegal and unregistered practices not only leads to unfair competition but also harms the circular economy.

Is the collected waste oil effectively used in the current situation?

As the stakeholders in the sector, we strive to utilize the collected waste oil in the best possible way and maximize our potential. However, the biggest challenge we face in waste oil collection is the unfair competition created by illegal and unregistered practices. In our country, a significant amount of waste oil is still being used in fuel production or involved in illegal and unregistered practices, leading to unfair profits and illegal competition in the market and the severe environmental damages caused by these practices continue to exist. Another issue is the lack of practical implementation of proper electronic recording systems like MOTAT in the field. So, those who possess waste oil prefer to deliver it to buyers off the record, resulting in a significant unfair competition.

We are collaborating with the relevant public institutions to address and resolve these issues. One of our most significant initiatives is the establishment of the Waste Oil Refining Industry Association (AYRASDER), in which we have pioneered. As AYRASDER, we are working to establish an effective and efficient waste oil collection system nationwide, aiming to ensure the proper collection and utilization of waste oil. We are taking initiative to increase public awareness and consciousness in this regard, highlighting the benefits of waste management and informing our stakeholders about the technical and professional aspects involved in the process.

As TAYRAŞ, could you tell us about the projects on your agenda, your short-term and medium-term goals?

One of the significant projects on our agenda is to establish a more effective and efficient joint waste oil collection system in Türkiye. We aim to transform this system into a strong solution center with the participation of all stakeholders in the lubricant industry. This issue is at the forefront of our priority projects. Additionally, we are focusing on increasing the utilization of renewable energy sources in our current production and creating more value in terms of sustainability with low carbon footprint. Furthermore, we are exploring opportunities to enter global markets with potential capacity expansion. In this context, we also aim to enhance our export capabilities by introducing our superior-quality base oils to international markets, and in doing so, we seek to further contribute to the country’s economy through the employment opportunities we generate.

TAYRAŞ has a considerably critical role in the circular economy. As a company that introduced the concept of “re-refining” to Türkiye, it not only contributes to the country’s economy by producing value-added products but also serves the future of our planet. TAYRAŞ’ successful initiatives are also being recognized and awarded by official institutions, professional organizations, and NGOs.

The environmental benefits of the production of base oils with advanced refining technology in waste oils have been proven by technical reports from independent and expert organizations

According to the life cycle assessment report published by GEIR in September 2022, which includes TAYRAŞ Base Oil Refinery, the environmental advantages of the production of base oils by re-refining waste oils compared to the production of base oils through the refining of crude oil can be summarized as follows:

- 70% less CO2 emission

- 90% less acidification

- 88% less release of the fine particulate organic matter

- 80% less eutrophication

- 87% less resource consumption

Furthermore, when comparing the advantages of re-refining process with the use of waste oil as fuel, the following data were shared in the same study:

- 47% less CO2 emission

- 34% less acidification

- 59% less release of the fine particulate organic matter

- 46% less eutrophication

- 15% less resource consumption

The report provides evidence of the environmental superiority of proper management of waste oil through eco-friendly technologies and the production of base oil from waste oil compared to using base oil obtained from crude oil or using waste oil as fuel.

TIDRABASE, the high-quality Group II+ base oil produced by TAYRAŞ from waste oil using hydro-treatment technology, has gained user satisfaction with its colorless and odorless characteristics and superior performance.