Today, the interest in renewable energy sources is increasing along with the rising demand for wind turbines. Maintenance and sustainability of these turbines are important as the conditions are harsh on wind farms; therefore the oils that will sustain their performance have a vital role.

Wind power offers various advantages as wind is a renewable and clean source of energy, the raw material is fully indigenous, the cost of wind power plants is competitive with other power plants, maintenance and operating costs are low, the technology used is relatively simple, and the power plant can be put into operation in a short period of time.

Wind power generation grew by 15.6 percent in 2016 to reach 4 percent of total world electricity generation. In 2016, new wind generation capacity of 55GW was added worldwide, with the total capacity reaching 487GW.

China leads the world in terms of installed wind capacity. According to the GWEC data, China contributed about 43 percent to the global installed wind capacity in the period from June to December 2016. The country added a newly installed capacity of 23GW to the wind generation industry in this period.

The record annual installations that were reached in 2015 at the global level created a significant revival in the wind sector. The newly installed capacity, which was 52GW in 2014, reached 64GW in 2015. Although there was a slowdown, 2016 was a year in which the sector developed new plans and made the necessary improvements for 2017.

Wind industry in Turkey

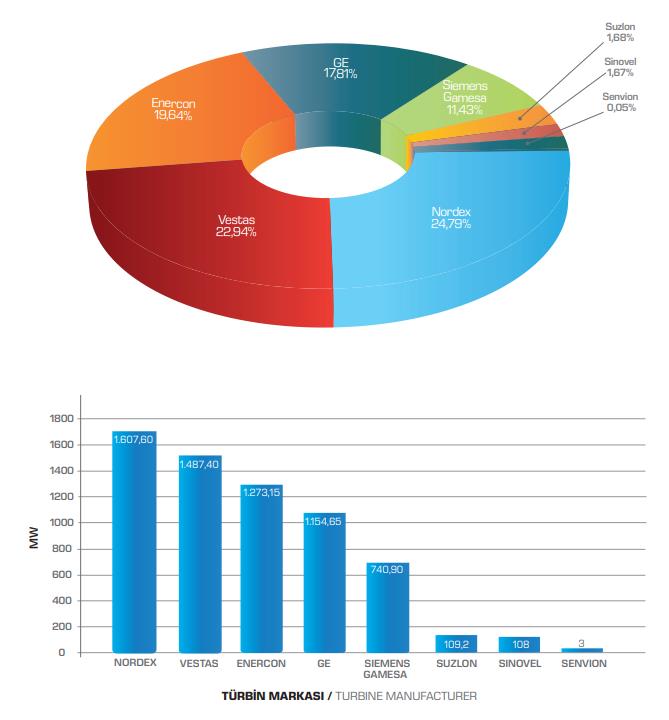

Turkey attaches great importance to renewable energy and thus it is increasing its cumulative installations for wind power plants. Increasing its cumulative installations value by 29.41 percent from 2015 to 2016, Turkey achieved an increase of 6.2 percent in the first half of 2016. The most profitable region for establishing wind power plants in Turkey is the Aegean region. Approximately 40 percent of the plants are located in the Aegean region, and 35 percent are located in the Marmara region. Currently, there are 158 wind power plants in operation throughout Turkey. Nordex and Vestas are the most preferred turbine manufacturers in these power plants. However, Nordex and Siemens seem to be dominant among the preferred manufacturers in the wind power plants under construction.

Chart 1: Operational wind power plants according to turbine manufacturers

Source: TUREB (Turkish Wind Energy Association)

The uptrend in wind power generation also contributes to the decline in carbon emissions. Global carbon dioxide emissions in 2015, which was a significant year for the wind industry, remained stable despite the growth in world economy. This was due to industrial restructuring, improved energy efficiency and substantial growth of renewables – led by wind.

As the share of renewable energy in the world energy mix increases, maintenance and sustainability of wind turbines has become an important issue on the agenda. Due to severe weather conditions that turbines are exposed to, durability and reliability are among the most important factors that operators have to consider.

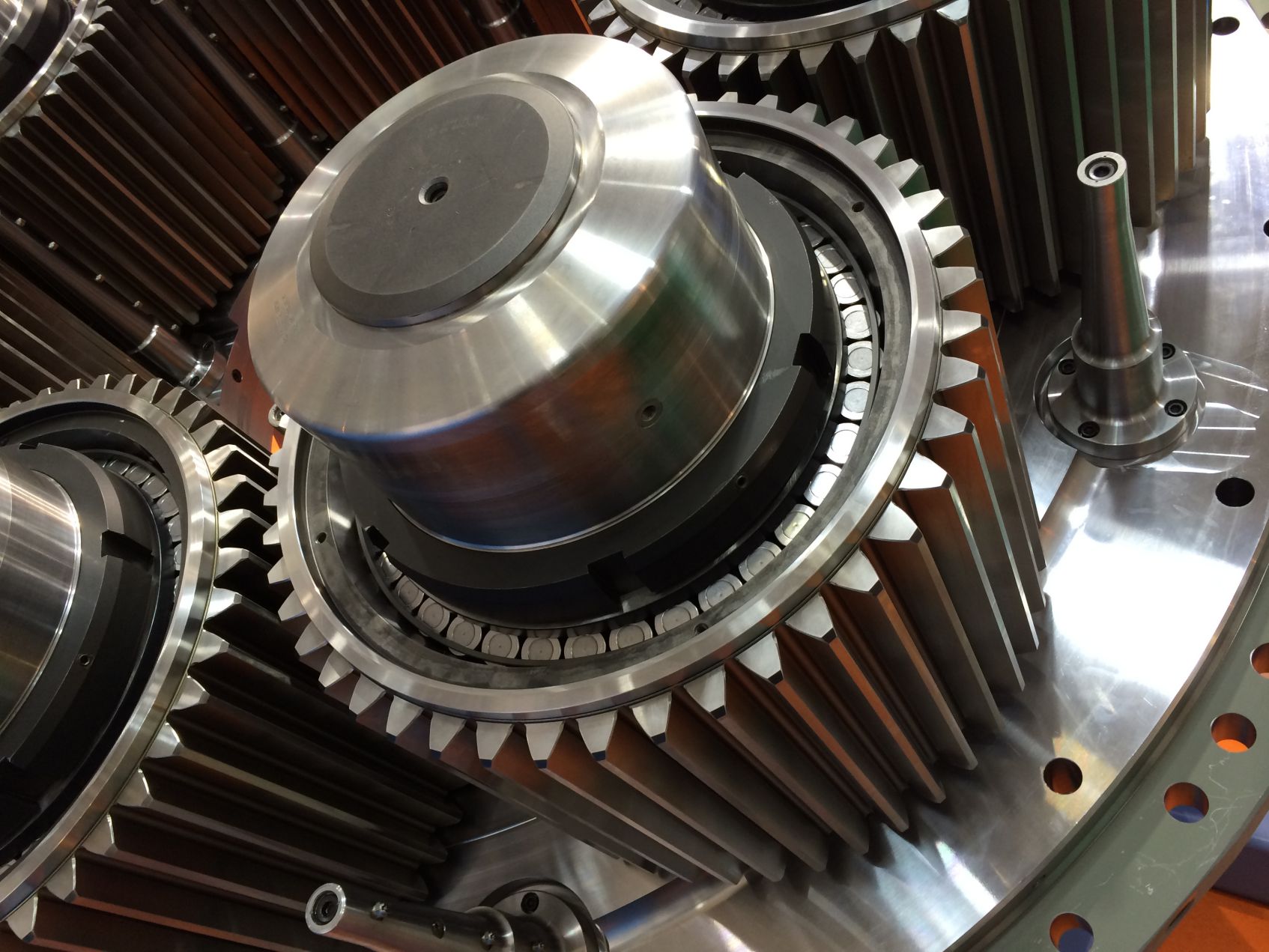

“Fluctuations in temperature and wind strength put a lot of strain on the gear systems of today’s wind turbines, which can weigh up to six tons. These gear systems cost approximately € 200,000, making it worthwhile to run them with oils that protect against wear and are weather and corrosion-resistant. Plus, an oil change at a height of 80 meters isn’t easy. Up to 600 liters of used oil must be pumped off with negative pressure, and then 600 liters of fresh oil must be pumped up with excess pressure. Therefore, wind turbine operators expect long service life and reliability from wind turbine gear oils. Specially formulated wind turbine gear oils are a significant contributor to the overall operating cost of wind power generation, especially the attendant costs of replacement and quality monitoring. Consequently, they offer innovative and sustainable solutions that not only extend performance, but also minimize costs. With additives of the NUFLUX™ brand, wind turbine operators can rely on having high-quality oil for a long time. In fact, they can wait twice as long before changing the oil,” says Mukund Bhure, Global Industrial Gear Oil Marketing Manager at Evonik.

Evonik has developed a wind turbine gear oil (WTGO) for critical OEM and owner/operator service requirements. Formulated with NUFLUX™ technology, additional Evonik-formulated components, as well as base fluids and additives from other suppliers, this WTGO meets or exceeds the performance of existing synthetic lubricants, even under the most demanding conditions.

To gain further insight into the wind industry and receive elaborate information about the role and efficiency of oils used in wind turbines, we interviewed Mr. Bhure.

“NUFLUX™ offers many advantages in wind turbines”

What is the importance of lubricants in wind turbines?

Within industrial applications, wind turbine gearbox lubrication is arguably the most challenging category. Wind turbine gearboxes perform within a wide range of operating conditions because of always-changing meteorological situations and power-generating demands. In addition, these systems are expected to perform with extraordinary reliability and to exhibit outstanding durability.

Because of their excellent overall performance, fully synthetic lubricants, largely formulated with higher grades of polyalphaolefins (PAOs), are the most widely used transmission fluids in wind turbines. These oils are relied upon to provide wear and fatigue protection, thermal and oxidative stability, foam resistance and shear stability. In addition to meeting these critical needs, these synthetic lubricants have also demonstrated their ability to provide long oil service lifetimes and to achieve good mechanical efficiencies.

The downside of relying on these types of synthetic lubricants is their high cost. Therefore the experts at Evonik Oil Additives have developed an oil to meet, or even exceed, the performance of a fully-synthetic lubricant, while providing better economics and worldwide supply security.

How do lubricants work in wind turbines?

It is obvious that the properties of the lubricant used in wind turbine gearboxes are crucial in protecting the bearings and gears from physical damage. Recent history suggests that a number of gearbox breakdowns have occurred due to micropitting and scuffing on the gears, or because of bearing failures.

Wind turbine gear oils must meet general industry specifications, like the DIN 51517-3 in Europe, or AGMA 9005/E02 in North America. Learning from field experience, including failures, OEMs have set up their own criteria and approval lists. These specifications are more stringent, and more accurately reflect true operating conditions, including severe low temperature requirements.

For these reasons, synthetic formulations are predominant in this application. Most of the wind turbine gear oil formulations on the market with OEM approvals are based on PAO-type base stocks in combination with esters to improve additive compatibility.

Formulations made with alternative high-viscosity base stocks are rare. Fully ester-based formulations are extremely costly and have disadvantages in terms of hydrolytic stability. Polyglycols are sometimes problematic in use because they are not cross-compatible with conventional lubricants, are hygroscopic and can cause issues with paints and coatings.

The formulation developed by Evonik Oil Additives showed outstanding performance in the FVA 54/2 micropitting test, in the FAG 4-step bearing test and in the FZG scuffing test. Furthermore, results from efficiency tests on gears and friction tests on bearings lead to the assumption that NUFLUX™ might contribute positively to the overall gearbox efficiency.

What do customers expect?

The market of WTGO is dominated by few large oil international oil companies. Some of the regional customers also are eager to enter in this growing and highly profitable niche segment but have limitations due to lack of access to international gear box OEM’s and bearing manufacturers for obtaining approvals which are complex, time consuming as well as expensive. Since NUFLUX™ comes with most of these approvals, it is perceived as a great assistance by customers.

What are the economic advantages?

Apart from the following technical advantages:

- High VI

- Excellent low temperature properties

- Gear wear protection, as well as excellent bearing protection

- Elastomer compatibility as good as PAO/ester formulations

NUFLUX™ also offers economic advantages since it is a novel ester-free formulation concept based on a group III base oil and a VISCOBASE® synthetic base fluid. Additional advantages of this new formulation include the global availability of its components, high supply security and reduced formulation cost.

What is your personal contribution in day-to-day business to the success and advancement of the products for this area of application?

We have ambitious plans to promote NUFLUX™ technology not only in the wind turbine segment but also to the general industrial gear oil segment. In this context, we are working to obtain further OEM approvals, and to strengthen the capabilities of our sales teams by providing adequate knowledge as well as promotional material. We are also closely working with some of our key customers to conduct field trials to develop testimonials which can be leveraged elsewhere.